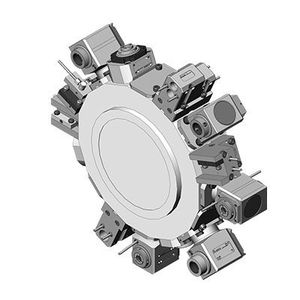

Automatic tool changer BENZ Hybrix serieswith rotary magazine

Add to favorites

Compare this product

Characteristics

- Type

- automatic

- Magazine

- with rotary magazine

Description

BENZ Hybrix is an innovative tool changing system which is directly coupled to a high frequency spindle.

Highest rigidity due to direct coupling spindle to tool changer

Economical, energy-efficient system due to the use of only one motor spindle

Space-saving machine concept

Highest precision due to fine positioning of the tool holder by the motor spindle

Very short tool change times

Process optimization through a high degree of automation

Less mass to be moved on each stroke

Cost savings as no separate tool changer is necessary

High speeds for a perfect machining result

High torque due to maximum motor length

Easy servicing due to modular design

Customer-specific adaptions possible

The technology is suitable for all machine types. Versions in star (single row, multi-row) and crown design are possible.

Power throghput / Forces and moments

Number of spindle rows

Number of tool places

In addition for the single-row star and crown design: linear stroke (magazine or motor spindle), tool clamping (direct or indirect)

VIDEO

Catalogs

No catalogs are available for this product.

See all of Benz Tooling‘s catalogsRelated Searches

- Chuck

- Machining tool holder

- Tool changer

- Aggregate head

- Machining unit aggregate head

- Automatic tool changer

- Machining spindle

- 90° aggregate head

- Machining center tool holder

- Adjustable angle head

- Tool changer with rotary magazine

- Spindle unit

- Multi spindle

- Lubrication spindle

- Motorized spindle unit

- Milling spindle unit

- Cutting spindle unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.