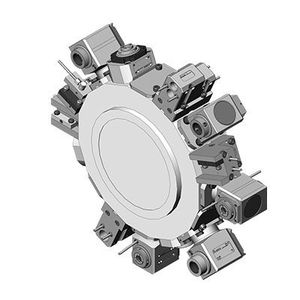

Machining center driven broaching unit LinA 4.0

Add to favorites

Compare this product

Characteristics

- Options

- for machining centers

Description

Broaching units from BENZ make it possible to machine materials that have high tensile strength. An eccentric is used to convert rotary motion from the drive shaft into linear motion on the drive side. The plunger dips into the workpiece with the cutter and removes material after the shaping process using the integrated lift-off device. At the same time, the lift-off device avoids wear and prevents the cutter from breaking during the return motion coming out of the workpiece.

Cost-effective manufacturing of a wide variety of shapes and profiles

Reduced set-up times and costs: Complete machining of workpieces in just one setting gives you a leaner production process and increases production speed

Increase in efficiency: Your productivity increases thanks to a reduction in machine operating time and downtime

Energy and resource-saving production: The shaping and lift-off function is carried out by the shaper and not by the machine. All of the kinematics of the shaping process are integrated into the powered shaper. No heavy machine components are moved for removing material.

Low investment costs: The broach is an auxiliary unit for your machine tool. There is no need to purchase separate machines, such as a broaching machine

Use of existing machine functions: The broach uses existing machine functions, such as the turret drive

Driven radial broaching units for all common CNC lathes

Driven axial broaching units for all common CNC lathes

Driven radial offset broaching units for all common CNC lathes

VIDEO

Catalogs

No catalogs are available for this product.

See all of Benz Tooling‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.