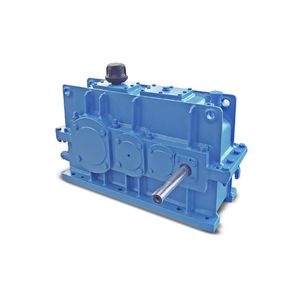

Bevel gear reducer EPEXhelical gearparallel-shaftmodular

Add to favorites

Compare this product

Characteristics

- Type

- bevel, helical gear

- Shaft orientation

- parallel-shaft

- Configuration

- modular

- Applications

- for single-screw extruder

- Other characteristics

- self-aligning

- Rotational speed

1,000 rpm, 1,500 rpm

(6,283.19 rad.min-1, 9,424.78 rad.min-1)

Description

Continuously working singe-screw extruder presses or single screw extruders, on account of their materials processing technology and construction demands on the driver assembly :

To be capable of transmitting the high torques for pressurising and plasticising moulding materials and synthetics required for fibre line production and secondly

Capability of absorbing the high thrust load induced by the process.

While the first point determines gearbox size and ratio, the axial forces and desired bearing life govern the axial bearing and its housing

In order to obtain an economical drive assembly which is adapted in the best possible way to the materials processing technical demands, Elecon has developed an

Extruder Gear Modular-Series EPEX

The Elecon extruder gear modular consists of a combination of Gear units (of different EP Series ) and flanged axial bearing housing for the take-up of axial self-aligning roller bearings of different load capacities.

According to their functions both these assemblies are to be designed independently of each other.

Selection :

Gearbox : page 8

Axial bearing page 2

From the combination of both assemblies the Elecon single shaft extruder gear is produced. Combination possibilities : Page 9

Catalogs

No catalogs are available for this product.

See all of BENZLERS‘s catalogsRelated Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Precision gearbox

- Flexible shaft coupling

- Compact gearbox

- Gear train gearbox

- Shafts coupling

- Solid-shaft gearbox

- Hollow-shaft gearbox

- Shaft gearbox

- Transmission gearbox

- Industrial gear reducer

- Helical gear gearbox

- Flange shaft coupling

- Single-stage gearbox

- Low-noise gearbox

- Bevel gearbox

- Multi-stage gearbox

- Two-stage gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.