- Products

- Catalogs

- News & Trends

- Exhibitions

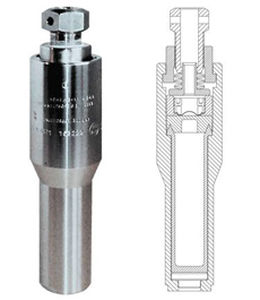

Laboratory reactor BR-25high-pressure

Add to favorites

Compare this product

Characteristics

- Applications

- laboratory

- Treatment method

- high-pressure

Description

The high-pressure reactors of the BR-25 and the BR-40 series are equipped with a valve, rupture disc and manometer as standard. Individual configurations and the use of PTFE inserts are possible at any time. The reactor lid fits to all vessel options. The low weight of the BR-25 and BR-40 reactors is the basis for a flexible use within the laboratory.

The high-pressure reactors BR-25 and BR-40 show off their strengths at minimum quantities approaches within organic matters or when working with fine chemicals. According to the customers’ needs, the reactors are made of stainless steel 316 Ti (1.4571) or hastelloy C-22 (2.4602). There are four vessel options available: the two standard vessels for BR-25 and BR-40, as well as the vessels for the use of PTFE inserts.

The high-pressure reactors BR-25 and BR-40 have several armatures:

Rupture disc, dip tube and valve are standard equipment

Pressure measurement is operated analog and/or digital

Two of the six ports are free for individual use. The connection type is a 1/8” tube connection. The number of free ports can be enlarged by the use of T-connections.

VIDEO

Catalogs

High_pressure_reactor

8 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.