- Products

- Catalogs

- News & Trends

- Exhibitions

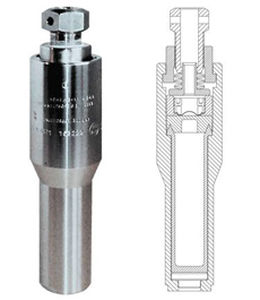

Laboratory reactor BR-1000high-pressure

Add to favorites

Compare this product

Characteristics

- Applications

- laboratory

- Treatment method

- high-pressure

Description

With heating or cooling system, with or without stirring: the BR-1000, BR-1500 and BR-2000 high-pressure reactors fulfil the most demanding requirements. Volumes up to 2,230 ml offer a large variety of possible uses within production and research, e.g. for synthesis and catalysts researches. Intelligent instrument concepts form the basis for an easy handling.

The scope of delivery for the high-pressure reactors BR-1000, BR-1500 and BR-2000 includes rupture disc, dip tube, valve and a tool for a proper opening and closing of the reactors. According to customer requests, the reactors can be manufactured with stainless steel 316 Ti (1.4571) or hatelloy C-22 (2.4602). Pressure measurement is made analog and/or digital.

Due to an extensive range of accessories, individual reactor configurations can be made easily. Examples of accessories are:

Different heating methods (integrated or via additional instrument)

Various stirring concepts

Sample holders

A number of control units

The BR-1000, BR-1500 and BR-2000 reactors can be used for volumes up to 2,230 ml and convince by an easy handling, which represents a high level of user friendliness. Amongst others, this can be traced back to the opening and closing tool. All reactor vessels can be equipped with PTFE inserts.

Catalogs

High_pressure_reactor

8 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.