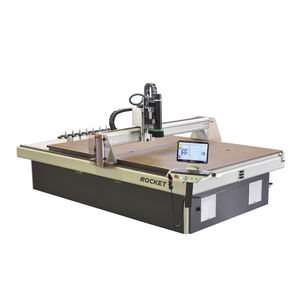

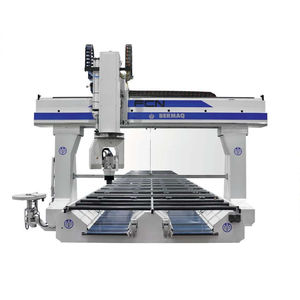

3-axis CNC milling machine VISCOMverticalfor woodacrylic

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Machined material

- for wood, acrylic

- Spindle mount

- HSK F63

- Associated functions

- engraving, cutting

- Applications

- foam

- Other characteristics

- high-performance

- X travel

3,100 mm, 4,100 mm, 5,100 mm

(122.05 in, 161.42 in, 200.79 in)- Y travel

2,050 mm

(80.71 in)- Z travel

360 mm

(14.17 in)- Rotational speed

12,000 rpm, 24,000 rpm

(75,398 rad.min-1, 150,796 rad.min-1)- Power

Max.: 15 kW

(20.39 hp)Min.: 8 kW

(10.88 hp)- Work feed X-axis

80,000 mm/min

(52 in/s)- Work feed Y-axis

80,000 mm/min

(52 in/s)- Work feed Z-axis

30,000 mm/min

(20 in/s)

Description

The CNC milling machine VISCOM is ideal for cutting, engraving, milling and rectifying different materials such as plastics and derivatives, acrylic, wood, foam, resins, non-ferrous materials, etc.

This CNC milling machine with high performance stands out for its great robustness, versatility and high-quality finishes. Capable of adapting to all kinds of projects and production rhythms, the BERMAQ® numerical control machine VISCOM guarantees great resistance to the high mechanization demands.

For this reason, it has become one of our customers’ favourite models.

The numerical control milling machine VISCOM has been designed, fundamentally, to work at high speed a wide variety of materials (plastics, woods, aluminium, resins, composites, etc.) and applications. This industrial CNC machine stands out for its robustness, versatility and quality, offering a guarantee of unbeatable productivity.

Its equipment with recirculating ball screws allows high precision in the machining and ensures a high-quality finish. At the same time, its strong structure guarantees greater resistance to continuous work and high machining requirements.

Its compact design makes it a robust and modular CNC milling machine. Its structure allows easy customization of the machine with optimal solutions according to the production requirements of each client. This model has a wide range of custom-made solutions to suit the needs of each project.

The VISCOM CNC milling machine model has become one of the most popular thanks to its easy operation, reliability, speed and, above all, the quality and precision of the finishes.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Gantry CNC machining center

- Bridge CNC milling machine

- Precision CNC milling machine

- Compact CNC machining center

- Machining center for the automobile industry

- High-power CNC machining center

- 5-axis CNC milling machine

- High-precision CNC milling machine

- Aluminum CNC milling machine

- High-performance CNC milling machine

- Cutting CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.