- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

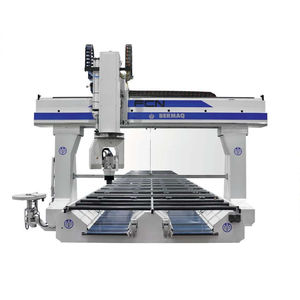

5-axis CNC milling machine VISCOM 5Xverticalbridgefor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- bridge

- Machined material

- for aluminum, for wood, for composites

- Spindle mount

- HSK F63

- Applications

- for the automobile industry, for aeronautics, for the plastics industry, for the aluminum industry, for the wood industry, foam

- Other characteristics

- high-performance, high-precision, high-productivity

- X travel

Min.: 1,550 mm

(61.02 in)Max.: 10,000 mm

(393.7 in)- Y travel

Min.: 1,000 mm

(39.37 in)Max.: 3,000 mm

(118.11 in)- Z travel

500 mm

(19.69 in)- Rotational speed

12,000 rpm, 20,000 rpm

(75,398 rad.min-1, 125,664 rad.min-1)- Power

11 kW

(14.96 hp)- Work feed X-axis

55 m/min

- Work feed Y-axis

55 m/min

- Work feed Z-axis

20 m/min

Description

The CNC milling machine VISCOM 5X has been designed to meet the most demanding machining requirements. Its high productivity, versatility, and state-of-the-art technology allow it to work a wide range of non-ferrous materials (aluminum, wood, foam, resins, plastics, methacrylate, composite, etc.) and to achieve all kinds of shapes and finishes.

This 5-axis interpolated CNC router with optimized control is used in machining processes that require high precision and complexity.

Thanks to its high customization capacity and multi-purpose performance, the VISCOM 5X is perfect for all sectors (from the graphic arts sector to the aeronautics sector). It is a machine designed to successfully machine general industry projects. This model is also manufactured in 3 axes: VISCOM.

The machining of materials with 5-axis machinery is an effective method for reducing the number of fixtures required to complete the entire workpiece and increasing precision when machining complex or multi-faceted parts.

This industrial CNC milling machine designed and manufactured by BERMAQ® stands out for its robustness, versatility, and quality, offering a guarantee of unmatched productivity. It has an electro-welded and thermally stabilized steel bed and bridge for high stability and reliability.

Its compact and optimized design makes it a robust and modular CNC milling machine. Its structure allows easy customization of the machine with optimal solutions according to the production requirements of each customer. This model has a wide range of customized solutions to meet the needs of each project.

VIDEO

Catalogs

No catalogs are available for this product.

See all of BERMAQ‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Gantry CNC machining center

- Bridge CNC milling machine

- Precision CNC milling machine

- Compact CNC machining center

- Machining center for the automobile industry

- 40 tools CNC machining center

- High-power CNC machining center

- 5-axis CNC milling machine

- High-precision CNC milling machine

- Mold CNC machining center

- Composite CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.