- Products

- Catalogs

- News & Trends

- Exhibitions

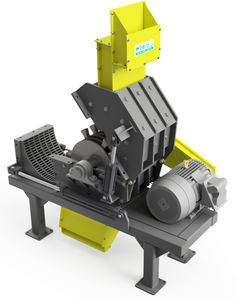

Double-shaft shredder hard disk drivefor data mediarotary shear

Add to favorites

Compare this product

Characteristics

- Number of shafts

- double-shaft

- Application

- hard disk drive, for data media

- Other characteristics

- rotary shear

- Power

Max.: 75 W

Min.: 15 W

- Output

Max.: 4 t/h

(2 lb/s)Min.: 1 t/h

(1 lb/s)

Description

Industrial cross-cut shredders are configured for high-speed destruction of documents and storage media other than hard disk drives. Two-counter rotating shafts with special cutters shear material to fixed widths while points on the cutters control the lengths of the shredded pieces.

Document destruction demands have become more stringent over time. Many financial, legal, and medical companies no longer consider documents destroyed if they are merely shredded into stips. Specific not-to-exceed shred lengths and widths are required. High volume shredding that provides a maximum 5/16” wide x 2-½” long shred size is considered by most companies to be full document destruction. Options are available for even smaller sizes for special applications.

Why does BESA lead?

BESA cross-cut heavy-duty precision shredders utilize improved 2020s manufacturing technology and designs, as compared to the majority of the industry relying on designs based on 1970s or 1980s manufacturing methods. BESA shredders are manufactured using CNC milling and lasers providing exact tolerances, fit and finish.

The speed of the shredder's feed conveyor is timed to match the rotational speed of the cutters to provide maximum throughput.

BESA shredders have hexagonal shafts rather than round shafts utilizing keyways. Hexagonal shafts have much greater mechanical engagement area between the shaft and cutters than the round keyed shafts. This allows for the shafts to handle far more torque.

VIDEO

Related Searches

- Grinding mill

- Waste shredding machine

- Vertical grinding mill

- Two-shaft shredder

- Metal shredding machine

- Paper shredding machine

- Rugged shredding machine

- Impact grinding mill

- Tire shredder

- Plastic pulverizer

- Hammer grinding mill

- Energy-efficient shredder

- Metal mill

- Four-shaft shredding machine

- Rotary shear shredder

- Hard disk drive shredder

- Data media shredder

- Paper mill

- Secondary pulverizer

- Tire mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.