- Products

- Catalogs

- News & Trends

- Exhibitions

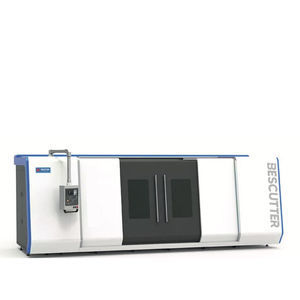

Servo-electric press brake CNCprecision

Add to favorites

Compare this product

Characteristics

- Operation

- servo-electric

- Control

- CNC

- Other characteristics

- precision

Description

Electric servo press brakes are highly versatile and suitable for a variety of applications, including precision sheet metal bending, small household appliances, and computer and equipment enclosures.

They are designed for bending metal materials and are well-suited for precision sheet metal components and mechanical manufacturing parts.

• Eco-friendly: Clean, pollution-free, and energy-efficient, eliminating the need for hydraulic oil.

• High Efficiency & Speed: Servo motors ensure fast speeds, precise bending, and reduced processing time compared to electro-hydraulic alternatives.

• Energy Savings: Consumes less electricity, saving an estimated 10,000 kWh per year, or 30%-50% reduction.

• Low Maintenance & Stability: No need for regular oil changes, with servo motors ensuring stable control and unaffected bending accuracy.

Key industries that benefit from all-electric servo press brakes

• Consumer electronics

• High-end switchgear cabinets

• Precision enclosures

• Medical equipment

• White goods (home appliances)

• Telecommunications

• Power distribution cabinets

• Various high-precision sheet metal products

MAIN COMPONENTS

• Main Motor: Ishcanto

• Linear Guide: HIWIN

• Ball Screw: TBI

• Electrics: Schneider

• Bearings: NACHI

• CNC Controller: DA66T

Related Searches

- Industrial press

- Hydraulic press

- Bender

- Automatic press

- Electric bender

- CNC bender

- Cutting press

- Press brake

- Production press

- NC press brake

- Press for industrial applications

- Sheet metal press

- Precision bender

- Precision press brake

- Sheet metal bending cell

- Blanking press

- Motorized bending machine

- Forming bending machine

- Electric press brake

- Mechanical bending machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.