- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

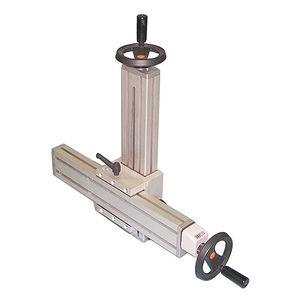

Electric positioner 1986linearsingle-axis positioningworm gear

Add to favorites

Compare this product

Characteristics

- Type

- electric

- Orientation

- linear

- Number of axes

- single-axis positioning

- Technology

- worm gear

Description

Use: positioning adjustable on one axis with worm screw for frequent adjustments, for combination with non-standard carriages constructed by the customer.

State of supply column in nickel-plated steel (electrolytic nickel-plating), trapeze or metric screw (see table) and lead nut in burnished steel, sliding bearings in brass or ball bearings in steel (see table), 2 DIN 7984 M6x20 socket head screws in galvanised steel.

Characteristics: Tr20 worm screw, pitch 4 (1 handwheel turn = 4 linear mm) or M20 worm screw, pitch 2.5 (1 handwheel turn = 2.5 linear mm).

Positioning accuracy: ±0.3 mm/300mm*.

Operation: STEP-BY-STEP (NO continuous operation).

Max. 120 rpm; max time: 1 (min; on/off ratio=1/10 (max 10%).

Millimetre scale marking p. .

WARNINGS

* the ACCURACY indicated is theoretical. Accuracy levels depend on the actual conditions of use and are affected by the accuracies of the kinematic chain - consisting of the handwheel/crank handle/revolution counter kit or any connection joints - and by the performance of the position control system (encoder, etc.).

Catalogs

Other BETT SISTEMI products

Connectors, positioners and format change units

Related Searches

- Screw jack

- BETT SISTEMI positioner

- Metal screw jack

- Drawer linear slide

- Roller linear slide

- Electric positioner

- Linear positioning system

- 3-axis positioning system

- Steel linear slide

- BETT SISTEMI linear positioner

- BETT SISTEMI 1-axis positioner

- Aluminum linear slide

- BETT SISTEMI manual positioner

- BETT SISTEMI 2-axis positioner

- High-accuracy positioning system

- Precision positioner

- Adjustable positioning system

- XY positioner

- Opposed movement positioning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.