- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

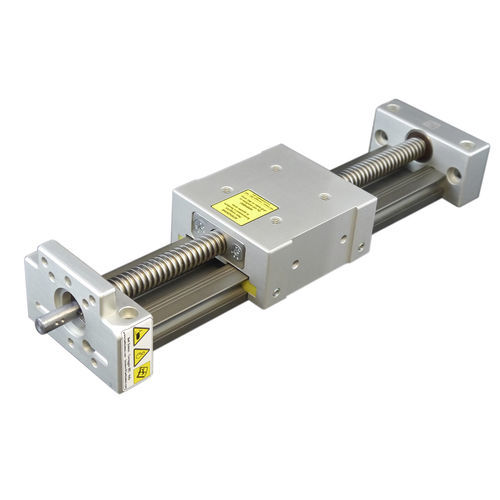

Linear array slide table M1P seriestrapezoidal screwmanualmotor-driven

Add to favorites

Compare this product

Characteristics

- Operation

- trapezoidal screw, manual, motor-driven

- Options

- linear array, compact, precision, positioning

Description

Use: accurate processing unit adjustment and positioning for product format changeover, with manual drive. The compact dimensions and customisable length make this linear table suitable when rigidity and reduced dimensions are required, ideal for dusty and dirty environments, silent and low-cost.

State of supply bronze-coloured anodised aluminium profile; 2 heads in anodised aluminium silver; 4 polyethylene screwcaps ; 4 UNI5939 M6x50 fastening screws in galvanised steel; 1 silver-coloured anodised aluminium carriage with 2 polyamide rollers and magnets for limit switches; 1 screw with trapeze threading in stainless steel AISI 304; lead nut in technopolymer; remaining nuts and bolts in galvanised steel.

Characteristics:

worm screw, Tr16 pitch 4 (1 turn = 4 linear mm).

Positioning accuracy: ±0.3 mm/300mm*

Carriage axial backlash: 0.15mm

Operation: STEP-BY-STEP (NOcontinuous operation).

Max. 120 rpm; max time: 1 min; on/off ratio=1/10 (max 10%).

the ACCURACY indicated is theoretical. Accuracy levels depend on the actual conditions of use and are affected by the accuracies of the kinematic chain - consisting of the handwheel/crank handle/revolution counter kit or any connection joints - and by the performance of the position control system (encoder, etc.).

Catalogs

No catalogs are available for this product.

See all of BETT SISTEMI‘s catalogsOther BETT SISTEMI products

Linear guides, linear tables and angular idlers

Related Searches

- Linear motion system

- Steel linear guide

- Slide linear motion system

- Metal shaft

- BETT SISTEMI ball joint

- Slide table

- BETT SISTEMI angled ball joint

- Metal joint

- Stainless shaft

- Precision slide table

- Steel joint

- Linear array slide table

- Compact slide table

- Transmission shaft

- Threaded joint

- Stainless steel ball joint

- Screw slide table

- Angle joint

- Universal joint shaft

- Positioning slide table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.