- Industrial machines and equipment

- Mixing and Dosing

- Dynamic mixer

- BHS-Sonthofen : Building Materials Machinery / Rec

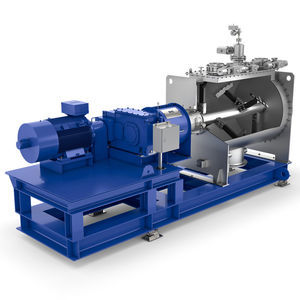

Twin-shaft kneader DKXC seriesdynamicbatchcontinuous

Add to favorites

Compare this product

Characteristics

- Technology

- dynamic

- Batch/continuous

- batch, continuous

- Product type

- solid

- Other characteristics

- twin-shaft, compact

- Applications

- construction

- Empty weight

Max.: 37,000 kg

(81,571 lb)Min.: 3,900 kg

(8,598 lb)

Description

Combimix processes (DKXC)

The patented Combimix system transforms the twin-shaft batch mixer (DKX) into a mixer that operates continuously according to the proven three-dimensional mixing principle. This results in a more intense mixing effect and a significantly longer average retention time compared to conventional continuous mixers. The material is extracted at the same rate as the input material is fed into the system.

BHS Combimix process for processing clay-and-rock mixtures in quarries

This nomination video for the German Resources Efficiency Award 2016 introduces the BHS Combimix process for processing clay-and-rock mixtures at the Mönsheim quarry operated by MSW Mineralstoffwerke Südwest.

Advantages compared to wet processing

• No introduction of moisture into the aggregates

• No wet sieving

• No sludge processing

• All materials are recycled, saving landfill space

• Compact system also available as a semi-mobile version

• High level of rock reclamation

• Possible to screen out material smaller than 5 mm

Advantages compared to conventional continuous mixers

• Continuous mixing process with a defined mixing time, which helps to reduce consumption of expensive burnt lime

• Three-dimensional mixing principle

• Consistently high mixture homogeneity

• High throughput rates

• Low wear

VIDEO

Catalogs

No catalogs are available for this product.

See all of BHS-Sonthofen : Building Materials Machinery / Rec‘s catalogsOther BHS-Sonthofen : Building Materials Machinery / Rec products

BUILDING MATERIALS MACHINERY - Mixers

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Grinding mill

- Solid blender

- Vertical agitator

- Horizontal grinding mill

- In-line mixer

- Powder blender

- Horizontal blender

- Construction agitator

- Impact grinding mill

- Compact agitator

- High-speed homogenizer

- Laboratory homogenizer

- Building materials grinding mill

- Recycling grinding mill

- Concrete kneader

- High-performance agitator

- Single-shaft blender

- Twin-shaft kneader

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.