- Industrial machines and equipment

- Mixing and Dosing

- Dynamic mixer

- BHS-Sonthofen : Building Materials Machinery / Rec

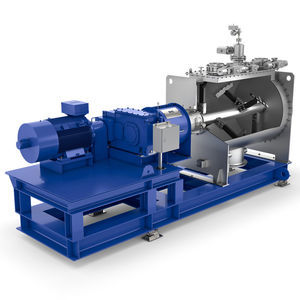

Dynamic kneader MFKG seriescontinuoushorizontalsingle-shaft

Add to favorites

Compare this product

Characteristics

- Technology

- dynamic

- Batch/continuous

- continuous

- Configuration

- horizontal

- Other characteristics

- single-shaft, weighing, gravimetric, metering

- Applications

- construction

- Engine power

Min.: 9.2 kW

(12.51 hp)Max.: 160 kW

(217.54 hp)- Empty weight

Min.: 900 kg

(1,984.2 lb)Max.: 8,500 kg

(18,739.3 lb)

Description

The single-shaft continuous mixer of type MFKG is a continuous mixing system that was developed for the intensive mixing of fine materials. Dry and moist, pasty as well as suspension-like mixtures can be produced continuously with the single-shaft continuous mixer. The special shape and arrangement of the mixing tools ensures an intensive mixing process. What sets the BHS single-shaft continuous mixer apart is the self-cleaning, flexible rubber trough, which prevents build-up on the inner trough wall. Liquids are added through nozzles in the inlet area, which facilitates early and extensive moistening of the entire feed material.

Benefits at a glance:

• - Consistently superior mixture quality

• - Self-cleaning rubber trough

• - Large maintenance flap

• - Secure investment thanks to high operational reliability

• - Low wear

• - Robust design

Consistently superior mixture quality

The design of the mixer inlet, the shape and arrangement of the mixing tools and the selection of the appropriate speed ensure a consistently high mixture quality. The high speeds cause highly turbulent relative movements in the mixture throughout the entire volume of the mixing trough, thus delivering consistently homogeneous mixing results in a very short time. Moreover, undesirable agglomerations are reliably broken up by shear forces.

Self-cleaning rubber trough

A unique selling point of the MFKG single-shaft continuous mixer is the self-cleaning process of the rubber trough. The pulsating motion and flexing effects of the rubber jacket prevent hardened mixing material from caking on the trough wall. Owing to this design, the mixer continuously cleans itself during operation.

Catalogs

No catalogs are available for this product.

See all of BHS-Sonthofen : Building Materials Machinery / Rec‘s catalogsOther BHS-Sonthofen : Building Materials Machinery / Rec products

BUILDING MATERIALS MACHINERY - Mixers

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Grinding mill

- Solid blender

- Vertical agitator

- Horizontal grinding mill

- In-line mixer

- Powder blender

- Horizontal blender

- Construction agitator

- Impact grinding mill

- Compact agitator

- High-speed homogenizer

- Laboratory homogenizer

- Building materials grinding mill

- Recycling grinding mill

- Concrete kneader

- Single-shaft blender

- High-performance agitator

- Twin-shaft kneader

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.