- Production Machines

- Other Manufacturing Equipment

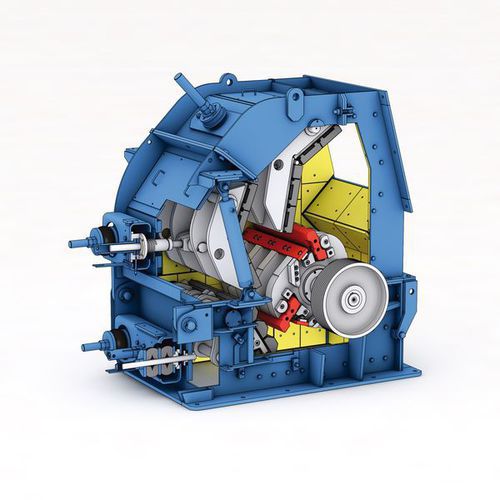

- Impact mill

- BHS-Sonthofen : Building Materials Machinery / Rec

Impact mill PM serieshorizontalbuilding materialsheavy-duty

Add to favorites

Compare this product

Characteristics

- Technology

- impact

- Orientation

- horizontal

- Product applications

- building materials

- Other characteristics

- heavy-duty, universal, robust

- Sector

- for recycling

- Output

Max.: 300 t/h

(184 lb/s)Min.: 40 t/h

(24 lb/s)- Motor power

37 kW, 250 kW

(50.31 hp, 339.91 hp)- Machine weight

Max.: 25,000 kg

(55,116 lb)Min.: 4,600 kg

(10,141 lb)

Description

Impact crushers and impact mills (HSI) are universal and, at the same time, economical solutions. The BHS impact crusher achieves very high crushing ratios in both the first and second stage. This results in a wide range of salable, cubical final products. The impact crusher can be repurposed into an impact mill for manufacturing finer grains by inserting a higher machine base and an additional grinding track. This flexible solution allows you to benefit from excellent crushing results and respond to changing project requirements at any time.

Benefits at a glance:

• - Excellent crushing performance

• - Powerful rotors and heavy-duty impact plates

• - Large feed opening, quick and simple blow bar replacement

• - Maintenance-friendly design

• - Optimized wear parts

Powerful rotors

There are a variety of rotors available depending on the specific task at hand. The BHS rotors feature a durable, welded design. All surfaces subject to wear are fitted with replaceable wear parts. The impact bars are replaced from above. Plus, they can be removed quickly and easily thanks to their patented mounting system.

Robust impact plates

Depending on the application, the impact bars are made of heavy-duty monoblock cast iron or a welded steel structure with replaceable wear elements. The impact bars also easily handle coarser feed material and can be optimally configured for the relevant crushing task. Impact plates are supported by durable, maintenance-free spring units.

Large feed opening

Catalogs

No catalogs are available for this product.

See all of BHS-Sonthofen : Building Materials Machinery / Rec‘s catalogsOther BHS-Sonthofen : Building Materials Machinery / Rec products

BUILDING MATERIALS MACHINERY - Horizontal shaft impactors (HSI)

Related Searches

- Grinding mill

- Horizontal grinding mill

- Vertical grinding mill

- Rotor lump breaker

- Impact grinding mill

- Waste lump breaker

- Building materials grinding mill

- Recycling grinding mill

- Robust lump breaker

- High-performance grinding mill

- Heavy-duty mill

- Universal mill

- Concrete grinding mill

- Biomass mill

- Mortar mill

- Asphalt mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.