- Machine-tools

- Finishing Machine

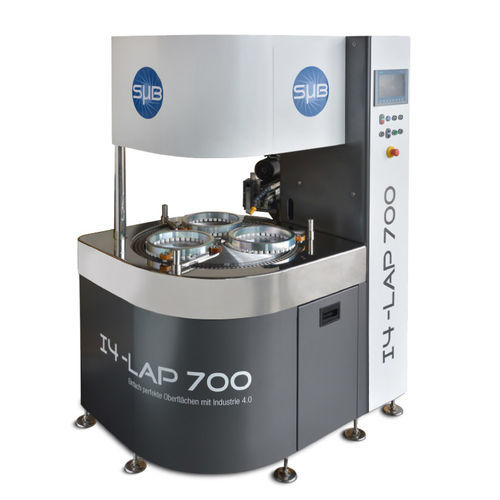

- Polishing lapping machine

- Bierther Submikron Gmbh

Polishing lapping machine I4-LAP 700CNCprecision

Add to favorites

Compare this product

Characteristics

- Options

- CNC, polishing, precision

- Outer diameter

700 mm

(28 in)- Inner diameter

275 mm

(10.83 in)

Description

The actual “Tech-Light” of Submikron – the new generation of singlesided lapping machines, the II4 LAP-series. Not only is the design new, this machine also offers new possibilities, such as the implementation of industry 4.0 specifications in the field of fine grinding, lapping and polishing. Together with the highly efficient LPS (Lapping Plate Profiling System) plate conditioning system and the CP8 Allrounder combined polishing-lapping in one plate, Submikron provides a well-rounded and reliable system for the lapping process.

Innovations

Innovative machine design

II4.0 integration of the machine into a production and process control system

Siemens S7 control with a 9-inch TFT widescreen display

Assemblies controlled by bus system

Recording and control of all important process parameters, such as speed, pressure, temperature, and stock removal

Integrated dosing for diamond suspensions and conventional lapping media

Lapping media and waste tank on two removable roll containers for easy handling

Central loading and unloading station for workpieces

Remote maintenance

Options when using LPS (Lapping Plate Profiling System)

Controlling and visualisation of the lapping plate flatness

Correction of the lapping plate by dressing on the machine

Spiral grooving of the lapping plate on the machine

Integrated dosing system of the I4 LAP

Number of dosing media: One dosing medium

Mixing: A lapping media pump with speed control and tank takes over the functions of stirring and conveying the lapping media. The speed control is necessary so that the abrasive in the lapping oil is not segregated.

Catalogs

No catalogs are available for this product.

See all of Bierther Submikron Gmbh‘s catalogsOther Bierther Submikron Gmbh products

Machines and dosing systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.