- Materials - Tools - Components

- Lubrication

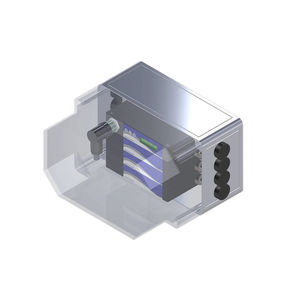

- Air/oil lubrication unit

- BIJUR DELIMON INTERNATIONAL

Air/oil lubrication system OS3 series for high-speed spindleselectric

Add to favorites

Compare this product

Characteristics

- Lubricant

- air/oil

- Applications

- for high-speed spindles

- Power source

- electric

Description

The Air-Oil Generating system delivers high efficiency lubrication for high-speed spindles and other

applications requiring accurate oil deliveries, in combination with air flow. The Air-Oil Generating Unit

is versatile and allows multiple configurations that enable systems to be designed to suit various

applications.

Application

The Air-Oil Generating Unit is a self contained lubricating system pre assembled and ready for

installation. The unit contains the following elements: an electric SureFire II Lubricator with

precision gear oil pump, proprietary electronic controller to operate and monitor all functions, Air

Treatment System (primary 5 micron filter and a secondary 0.01 micron coalescing filter), On-off Air

Solenoid and an Air-Oil mixing manifold to inject oil into the air delivery tubing. The Air-Oil Generating

system monitors and includes oil level warning, oil low level cut-out and two pressure monitoring

devices. The proprietary control works in conjunction with optional “OSS” Oil Streak Sensing Units to

monitor downstream oil particles flowing to critical bearings. The SureFire II Controller operates in

real time and has 2 internal relay outputs which can be connected to a host computer/PLC to monitor

the system status and fault type if any. The control can be reset at the SureFire II Lubricator.

The Air-Oil Generating Unit is designed to deliver small amounts of lubricant in a uniform and

continuous feed basis. The oil is injected periodically into the output air stream every 1~5 minutes

and depending on oil viscosity and air pressure, delivers continuous particles of lubricant to the

bearing.

Catalogs

No catalogs are available for this product.

See all of BIJUR DELIMON INTERNATIONAL‘s catalogsOther BIJUR DELIMON INTERNATIONAL products

SPECIAL LUBRICATION PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.