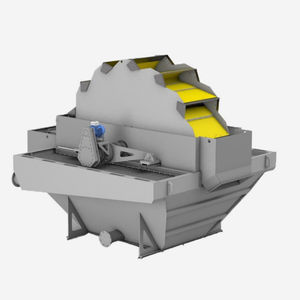

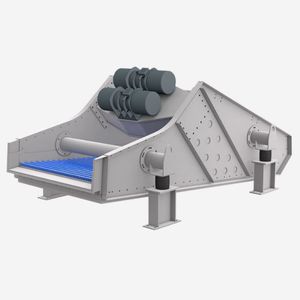

Water cleaning machine automaticprocessindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- water

- Operational mode

- automatic

- Applications

- process, industrial, sand

Description

Binder+Co’s log washer provides ideal preparation for further classification, in order to free the raw material of brittle grain and clay clumps. Even strongly contaminated raw materials for construction and industrial minerals can be processed highly efficiently.

Binder+Co’s log washer at work

The cleaning process starts with transferring the contaminated materials into the log washer at the lower end of the tub. The counter-rotating paddles transport the material to the upper outlet of the tub. The impact stress and effect of friction crushes the loamy and clay-containing elements so that they can distribute themselves in the water. The cleaned material is discharged at the upper end of the tub, and foreign particles and light materials are separated in the water at the lower end of the tub.

Catalogs

No catalogs are available for this product.

See all of Binder+Co AG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.