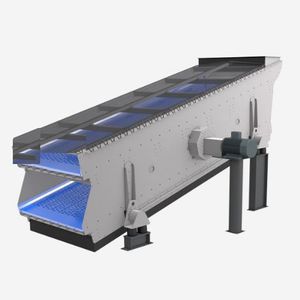

Flip-flow screener BIVITECdry screeninglinear vibratingfor bulk materials

Add to favorites

Compare this product

Characteristics

- Function

- dry screening

- Type

- linear vibrating

- Material

- for bulk materials

- Other characteristics

- inclined, flip-flow

- Screening surface

Min.: 1.5 m²

(16.1 ft²)Max.: 42 m²

(452.1 ft²)

Description

The BIVITEC flip flow screen comes into its own when conventional screening technology starts to be inefficient and uneconomical. Particularly challenging tasks are solved in a simple and efficient way. The BIVITEC flip flow screen ensures selective screening of bulk materials which are difficult to screen.

With the help of resonance, a driving mechanism provides two vibratory movements in which the flexible polyurethane mats are expanded and compressed in turns, and the hard-to-screen product is separated at high acceleration. The dynamically agitated screen mats thus remain unobstructed and allow efficient screening.

The simplest solution for screening bulk materials hard to screen.

Screening is an important step in the processing of bulk materials. Next to conventional screens, such as circular vibrating screens and linear vibrating screens, Binder+Co also supplies screens for especially difficult requirements.

Advantages of the BIVITEC Flip Flow Screen

Wear to the sides of the screen is prevented by the ox-horn system (laterally raised screen panels).

Screw less fastening system of screen panels allows them to be replaced fast.

Optimum adjustment to the task in hand by simply changing the vibration parameters.

Optimum side sealing by means of the ox-horn system avoids loss of material.

Optional monitoring of bearing and amplitudes for coordination and planning of maintenance intervals

VIDEO

Catalogs

Related Searches

- Screening unit

- Bulk material screening unit

- Vibrating sieving machine

- Mobile screening unit

- Recycling screening unit

- Dry screening sieving machine

- Construction screening unit

- Linear vibrating screening unit

- Process screening machine

- Inclined screening unit

- Circular vibrating sieving machine

- Double-deck screening machine

- Wet screening sieving machine

- Wet sieving machine

- Drainage screener

- Flip-flow screener

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.