- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

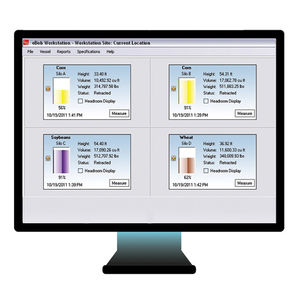

Monitoring software CementViewstorageschedulinginventory management

Add to favorites

Compare this product

Characteristics

- Function

- monitoring, storage, scheduling, inventory management

- Applications

- for silos

- Type

- real-time

- Deployment mode

- cloud-based, cloud

Description

CementView combines level sensor technology and cloud inventory software tailored specifically to the needs of cement and concrete batch plants so they can easily monitor material stored in silos, reduce material shortages and keep production moving.

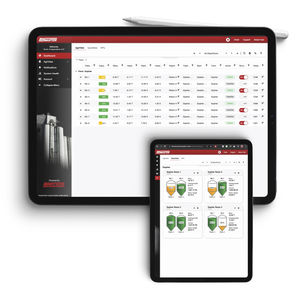

CementView® leverages the power of the latest level sensor technology and a simple Cloud-based software to reduce material shortages and production stoppages. It makes monitoring inventory contained in silos and storage tanks a faster, safer, and less tedious task. CementView® ensures you know how much material is in each vessel which is critical to processing operations. It does away with unwanted inventory discrepancies that create production headaches and negatively impact profitability.

How CementView™ Benefits Plants

Know how many truckloads of a given material will fit in a silo

Improve visibility of inventory for central dispatch

Eliminate climbing silos and dropping tape measures

Optimize scheduling for raw and finished materials

Visibility of multiple locations to optimize delivery routing

Streamline logistics between the cement plant, batch plants, and suppliers

Uses

Real-time inventory so that plants can plan and meet material demands for daily deliveries

Used in planning to set priorities, reduce out-of-stocks, and eliminate delivery emergencies

Providing dispatchers visibility of inventory at all sites to improve coordination of deliveries

Helping with routing drivers to the silos and plants with the most critical needs

Help prevent messy overfills and unwanted cleanup by ensuring the entire load will fit in the silo

Measuring sand, aggregates, cement, flyash, liquid additives, chemicals,

Catalogs

No catalogs are available for this product.

See all of BinMaster‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Windows software solution

- Control software solution

- Real-time software solution

- Online software

- 3D software solution

- Monitoring software solution

- Interface software

- Measurement software

- Automated software

- Network software solution

- Reporting software solution

- Tracking software solution

- Internet-based software

- Storage software

- Connectivity software

- Scheduling software

- Foundation software

- Scanner software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.