- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Acoustic level and volume sensor 3DLS M bulk solidsRS-485HART

Add to favorites

Compare this product

Characteristics

- Technology

- acoustic

- Medium

- bulk solids

- Interface

- 4-20 mA, HART, Modbus, RS-485

- Applications

- for silos, for storage tanks, for hazardous areas

- Approvals

- ATEX

- Other characteristics

- with 3D surface mapping, self-cleaning, intrinsically safe, ATEX, IECEx

- Level range

61 m

(200'01" )- Process pressure

Min.: -0.2 bar

(-2.9 psi)Max.: 3 bar

(43.51 psi)- Process temperature

Min.: -40 °C

(-40 °F)Max.: 85 °C

(185 °F)

Description

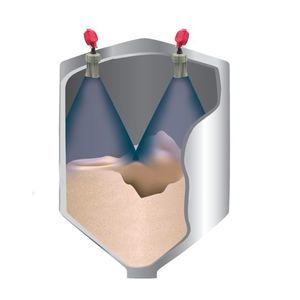

Get connected to your inventory with the only level sensor that measures and maps multiple points on the material surface. A 3D image representing the topography inside the silo indicates buildup, cone up or down conditions. 3DVision software accounts for irregular material surfaces when calculating volume.

The 3D Level Scanner’s acoustics-based technology penetrates dust ensuring reliable measurements. This non-contact technology accurately measures solids and powders, including low-dielectric materials. It is hazardous location certified for CFM Class I & II and IECEx/ATEX.

And you can get it only from BinMaster.

The 3DLevelScanner uses acoustics-based technology. Three transducers send extremely low frequency sound waves to the material surface, making a sound that sounds like chirping crickets. The sensor receives echoes back from multiple points on the surface which are converted to distance measurements.

Advanced algorithms in the software assign each measurement an XYZ coordinate that is mapped into a 3D image. Optional software generates a graphical representation of the material topography in the bin. Surface variations are accounted for in volume calculations.

What makes the 3D Scanner unique?

Measures multiple points on the material surface

Generates a 3D image of the material topography

Volume accuracy surpasses any single-point device

Reports minimum, maximum, and average distances

Detects cone up or down conditions

Sees sidewall buildup that could cause structural damage

Measures topography in segmented silos

Accurate volume in large bins using multiple scanners

VIDEO

Catalogs

No catalogs are available for this product.

See all of BinMaster‘s catalogsRelated Searches

- BinMaster level switch

- BinMaster level sensor

- BinMaster liquid level switch

- BinMaster liquid level sensor

- Pressure switch

- BinMaster analog level sensor

- Mechanical pressure switch

- BinMaster protection level level switch

- Level transmitter

- Stainless steel level limit switch

- Digital output level probe

- BinMaster threaded level switch

- BinMaster storage tank level sensor

- Diaphragm pressure switch

- BinMaster tank level switch

- Plastic level switch

- Liquid pressure switch

- Stainless steel level probe

- BinMaster IP68 level sensor

- Flow switch

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.