- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Acoustic level and volume sensor RLbulk solidsRS-485HART

Add to favorites

Compare this product

Characteristics

- Technology

- acoustic

- Medium

- bulk solids

- Interface

- 4-20 mA, HART, Modbus, RS-485

- Other characteristics

- with 3D surface mapping, self-cleaning, economical, with digital display, IP67

- Process pressure

Min.: -0.2 bar

(-2.9 psi)Max.: 3 bar

(43.51 psi)- Process temperature

Min.: -40 °C

(-40 °F)Max.: 85 °C

(185 °F)

Description

3D acoustic level sensor RL - standard with 7.67” diameter horn, 20-32 VDC, 4-20 mA output, Modbus, and RS-485 communications. Determines the average volume of stored materials based on a 15º beam angle in silos up to 14’ diameter and 200’ tall. Unit comes with internal LCD display and 3DVision software. Hazardous location approved, FM listed for Class I, II, Division 1, Groups C, D, E, F & G. One year warranty.

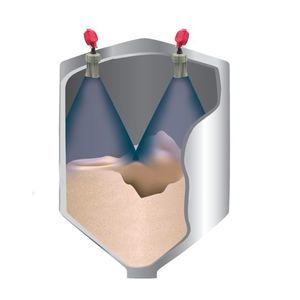

3DLevelScanner: Multiple Point Measurement for Accurate Volume

Advanced acoustics technology measures material topography in dusty environments for effective non-contact volume measurement.

Need volume accuracy in irregularly piled materials? 3D visualization to detect sidewall buildup?

Advanced acoustics-based technology is a proven performer in dusty powders and bulk solids.

5 Ways 3D is different:

Most level sensors only measure a single point

Optional 3D visualization of material topography

Detects cone up, cone down, and sidewall buildup

Provides minimum, maximum, and average distances

Accounts for surface irregularities for accurate bin volume

3D excels in unevenly piled material:

Grain, seed, feed, and food processing

Ethanol, bioenergy, and power plants

Aggregates and cement

Mining and metals

Chemical processing and plastics manufacturing

Pulp, paper, and wood pellets

VIDEO

Catalogs

No catalogs are available for this product.

See all of BinMaster‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.