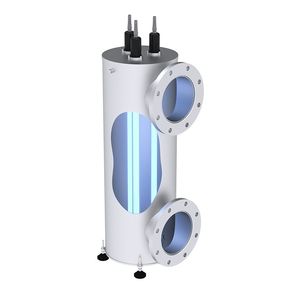

Reverse osmosis water purification unit IAMUV

Add to favorites

Compare this product

Characteristics

- Options

- reverse osmosis, UV

Description

IAM (LOW PRESSURE, CLOSED REACTOR) RANGE FOR THE TREATMENT OF INDUSTRIAL PROCESS WATER

BIO-UV Group water purification units are designed to treat industrial process water. They provide operators with the ability to protect their production and guarantee satisfactory water quality.

Principal applications for BIO-UV water purification units include:

- Disinfection of industrial process water

- Disinfection of wash and rinse water

- Downstream protection of membrane filtration systems (reverse osmosis, ultrafiltration, etc.)

- Maintaining stored water quality: raw water, treated water, ultra-pure water

- Dechlorination: to reduce free chlorine levels

- Dechloramination: to reduce combined chlorine levels

Advantages:

- UV control sensor meeting the Austrian ÖNORM standard ensures the continuous and proper operation of the UV reactor

- LCD display of UV intensity, remote management via 4-20 mA outlet

- Reactors can be customised according to installation, operation, and maintenance restrictions (flange diameter, inlet/outlet position, vertical/horizontal reactor, etc.)

- Single-base lamps and patented sealing system for easy maintenance

- Manual or automatic quartz sleeve cleaning system with no dismantling (depending on selected option)

- Lamp life: 13,000 hours

Benefits:

- Easy-to-implement treatment that does not alter the physical-chemical characteristics of the water: no change in taste, odour, etc.

- No creation of disinfection by-products harmful to human health

- No risk of under- or over-dosing

- No chemical monitoring or handling constraints

- Can be used in combination with other treatment processes

Catalogs

No catalogs are available for this product.

See all of BIO-UV Group‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.