- Products

- 3-blade impeller

- Biotehniskais centrs

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

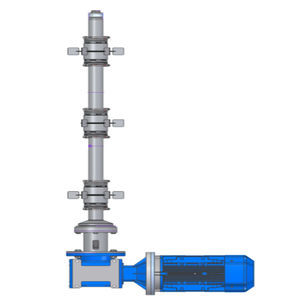

3-blade impeller

Add to favorites

Compare this product

Characteristics

- Configuration

- 3-blade

Description

Thanks to the novel design of our magnetic rotors, flow stagnation in the air gap between the outer rotor and the containment housing is fully eliminated, which is crucial for CIP and SIP procedures. All of our magnetic rotors are delivered as ready-to-use equipment, which can be installed on the designated magnetic mixer in a matter of minutes. The full mixer assembly comes with a complete set of parts for immediate operation. The standard package includes:

Magnetic rotor body (with suction slots and ZrO2 bushings)

Impeller blades (welded on or detachable)

Pair of SiC bushings

Additional parts (gaskets, impeller clamps, screws, etc.)

Our novel impeller solution for highly viscous Non-Newtonian fermentation broths. Thanks to the combined powerful axial/radial liquid flow, which is generated by our impeller, mass transfer is enhanced even in the close vicinity of the fermentation vessels wall.

Catalogs

No catalogs are available for this product.

See all of Biotehniskais centrs‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.