- Products

- Catalogs

- News & Trends

- Exhibitions

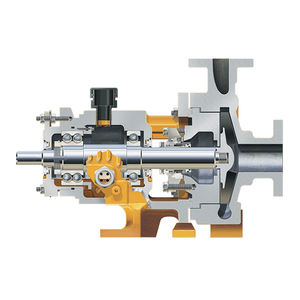

Centrifugal pump Frame A/LD17waterstationaryindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Fluid

- water

- Mobility

- stationary

- Domain

- industrial

- Applications

- process

- Other characteristics

- standard, heavy-duty, flow, built-in, seal

- Flow

320 m³/h

(11,300.69335 ft³/h)- Fluid temperature

400 °C

(752 °F)

Description

The Frame A and LD17 Centrifugal Pumps are pioneering process pumps with the built-in technology to get the most from seal and bearing life. Designed around the seal where 90% of pump failures occur, these centrifugal pumps have a stiffer, heavy-duty shaft and larger bearings resulting in the widest operational window off the Best Efficiency Point (BEP) than any standard process pump. These pumps come in 11 different sizes, meaning they are applicable for a wide range of fit scenarios and application needs.

The Frame A/LD17 has the stiffest shaft in the industry, which dramatically reduces seal and shaft failures. The Frame A/LD17 reaches flow capacities of 1,400 gpm (320 m3/hr) and is available in IPP metric construction.

Features and Benefits

Larger bearings than competing pumps for greater load capacity and bearing life

Bolted retainer cover locks thrust bearing into cartridge for enhanced reliability

Angular contact thrust bearings

Low maintenance, long life, maximum value process pump

Most stable shaft in the industry

Lowest L3/D4 stiffness ratio of any competitive size pump – 17 (.65) Frame LD17

Dramatically reduces bearing, sealing device and shaft failures

Frame A meets ASME/ANSI dimensional specifications

LD17 configuration available for severe-duty applications

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.