- Products

- Catalogs

- News & Trends

- Exhibitions

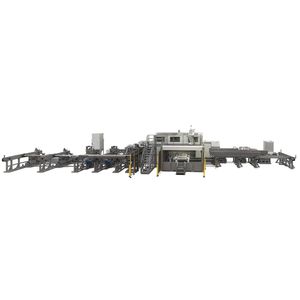

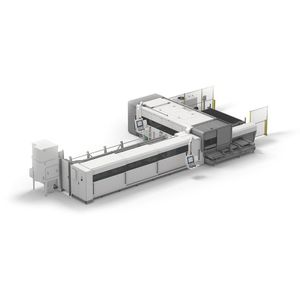

Fiber laser cutting machine LT143D laserfor stainless steelfor aluminum

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser, 3D laser

- Material

- for stainless steel, for aluminum, for brass

- Associated function

- for welding

- Other characteristics

- mild steel

- Tube diameter

355 mm

(14 in)- Laser power

3,500 W

Description

LT14 FIBER

Fiber laser cutting is all grown up

3D laser cutter for tubes up to 355 mm (14”) in diameter, open and special shaped structural beams

LT14 FIBER: 3D laser cutter for structural beams and tubes

•processing large tubes up to 100 kg/m (67 lb/ft)

•loading and unloading lengths up to 18 m (60’)

•fully automatic adjustments

•3D cutting with fiber laser source up to 3.5 kW

•cuts tubes, structural beams and open or special profiles (IPE)

•cuts all metals including highly reflective alloys: mild steel, stainless steel, aluminium

A new perspective for cutting large diameters

The LT14 FIBER cuts large diameter tubes rapidly and accurately by use of an innovative structure that rapidly moves the cutting head, not the tube. With this approach, you can obtain neater and more accurate geometries because the tube is gripped once at the beginning and is not released until the end of processing.

Zero scrap. The end of scrap and waste

The two through chucks have dual functions; both rolling the tube and clamping it.

This way the tube is never released thus making the cuts more accurate.

The cutting head automatically travels from one side of the chuck to the other according to the geometries to be made and utilizing the entire length of the bar without producing scrap.

The advantages of fiber laser cutting

Laser cutting of thick-walled tubes, such as structural beams, provides cost and part quality advantages when compared to traditional plasma or oxygen cutting. The laser performs accurate cuts needed to meet the required tolerances; without the need for grinding or other re-work. The laser cut edges are ready for welding without any additional weld prep.

VIDEO

Catalogs

No catalogs are available for this product.

See all of BLM GROUP‘s catalogsRelated Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- Metal sawing machine

- Sheet metal cutting system

- Automatic sawing machine

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- Sheet cutting system

- Cut-off sawing machine

- High-performance cutting system

- Compact cutting system

- Steel cutting system

- Profile sawing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.