- Machine-tools

- Finishing Machine

- Surface grinding machine

- Blohm Maschinenbau

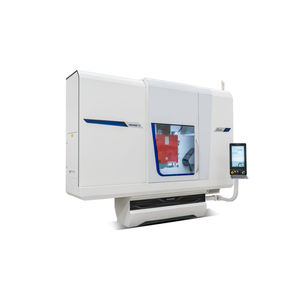

Surface grinding machine PLANOMAT XT EssentialworkpieceuniversalCNC

Add to favorites

Compare this product

Characteristics

- Type

- surface

- Applications

- workpiece

- Structure

- universal

- Control type

- CNC

- Number of axes

- 3-axis

- Features

- creep feed

- Other characteristics

- high-precision

- Spindle speed

3,500 rpm

(21,991 rad.min-1)- Power

11 kW

(14.96 hp)- X travel

1,100 mm, 1,500 mm

(43.31 in, 59.06 in)- Y travel

800 mm

(31.5 in)- Speed

2,000 mm/min, 30,000 mm/min

(1.31 in/s, 19.69 in/s)- Machine weight

7,300 kg, 7,600 kg, 8,500 kg, 8,900 kg

(16,093.75 lb, 16,755.13 lb, 18,739.29 lb, 19,621.14 lb)

Description

The competitive 3 axis entry level machine for high precision surface and profile grinding

Defined scope ofsupply

Siemens MC 1720 control

BLOHM single piece production with graphical operator guidance

Grinding technologies: Reciprocate grinding, Creep feed grinding

Design Features

Extreme rigid ductile cast iron components

Elevated Z axis guideways

Linear guideways in all machine axes

Re circulating ballscrews incl. Siemens drives in all machine axes

Grease lubricated grinding spindle with BLOHM transverse stop

Enclosure and coolant trough designed as weldment

Large sliding door running on the outside of the enclosure

Maintenance doors on the left and right hand side

Hardware / Software

Additional available options for surface and profile grinding applications

Automatic grease lubrication system for guideways and re circulating ballscrews

Linear scales for Y-/ Z-axis

Electro permanent magnetic chuck 1200/800 x 600/400 mm, DQ 13

Riser for magnetic chuck

Universal dressing unit, tiltable type, incl. pneumatics

Profile dressing attachment PA T 40, PA TLR 40, PA T 150S or PA T 200S

Manuel balancing unit

Coolant mist exhaust units

SIEMENS SINUMERIK MCU 1720

The BLOHM operator interface with graphical operator guidance adapts the control system perfectly to the needs of profile and contour grinding applications

User friendly with comfortable programming functions

Particularly suitable for the production of single parts and small series

Simple set up of machine and parameter

Quick adaptation of grinding and dressing cycles with graphical support

Tool management for 50 grinding wheels and 15 dressing tools

Catalogs

PLANOMAT XT ESSENTIAL

12 Pages

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Flat grinding machine

- Cylindrical grinding machine

- High-precision grinding machine

- External cylindrical grinding machine

- Vertical grinding machine

- Internal cylindrical grinding machine

- 3-axis grinding machine

- Stationary grinding machine

- Universal grinding machine

- High-performance grinding machine

- High-productivity grinding machine

- High-speed grinding machine

- Horizontal grinding machine

- Compact grinding machine

- Direct-drive grinding machine

- Multi-spindle grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.