Laser measuring system LC50-DIGILOGCNCtoolnon-contact

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Operating mode

- CNC

- Measured material

- tool

- Other characteristics

- non-contact

Description

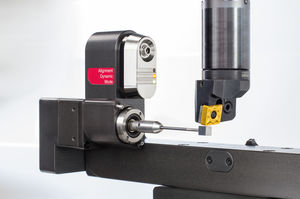

Laser measuring system for CNC machine tools that is unique worldwide for non-contact tool measurement and tool monitoring under the harshest conditions. Unbeatably fast, precise and reliable thanks to the latest DIGILOG technology, premium laser optics and perfected BLUM protection system.

The world’s most advanced laser measuring system

•Highly dynamic measurement of all tool parameters

•Non-contact measurement of all tool types, shapes, and cutting materials

•Recognition of changes in geometry such as tool cutting edge wear

•Consistently good part precision through process-integrated temperature compensation

•Reliable compensation for spindle drift and runout errors

•Run-out monitoring detects bad tool holders and soiling

•Low-manpower, automated operation

•Protected by patents

Unique DIGILOG Technology

•Up to 60% less measuring and checking time

•Thousands of measuring values of all tool cutting edges per second

•Evaluation of a data stream

•Dynamic adjustment of the measuring speed according to the nominal tool rpm

•Automatic filtering of dirt and cooling lubricant residue on tool

•DIGILOG calibration with integrated run-out monitoring

•In-process reliability under coolant in a new dimension

BLUM standard measuring cycles

The measuring cycles for BLUM laser measuring systems can be used to measure and monitor over 90 % of all conventional cutting tools. The measuring cycles are available for many conventional controls. Your local BLUM-representative will gladly inform you about the range of features for your control.

VIDEO

Catalogs

LaserControl Series

11 Pages

Related Searches

- Measuring machine

- Test stand

- Automatic test stand

- Micrometer

- Optical measuring machine

- Automatic measuring machine

- Pressure test stand

- High-precision measuring machine

- Industrial test bench

- Touch probe head

- Measuring system for industrial applications

- Parts measuring machine

- Hydraulic test stand

- Manual test stand

- Control measuring machine

- Measurement touch probe head

- Non-contact measuring machine

- Laser measurement system

- Test stand for the automotive industry

- Material test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.