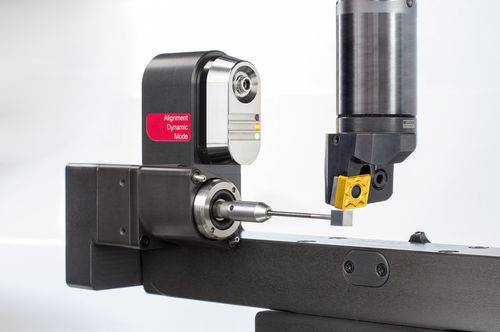

Laser measuring system with 3D touch probe for setting and monitoring the entire tool spectrum of combined turning/milling machines. Unbeatably precise and reliable thanks to the latest DIGILOG technology, premium laser optics and adapted 3D probe.

LC52-DIGILOG – The all-rounder suitable for every tool. Combines the benefits of two measuring technologies in one compact system.

The world’s most advanced laser measuring system

•Highly dynamic measurement of all tool parameters

•Non-contact measurement of all tool types, shapes, and cutting materials

•Recognition of changes in geometry such as tool cutting edge wear

•Consistently good part precision through process-integrated temperature compensation

•Reliable compensation for spindle drift and run-out errors

•Automatic run-out monitoring detects bad tool holders and soiling

•Low-manpower, automated operation

•Protected by patents

Unique DIGILOG Technology

•Up to 60% less measuring and checking time

•Thousands of measuring values of all tool cutting edges per second

•Evaluation of a data stream

•Dynamic adjustment of the measuring speed according to the nominal tool rpm

•Automatic filtering of dirt and cooling lubricant residue on tool

•DIGILOG calibration with integrated run-out monitoring

•In-process reliability under coolant in a new dimension