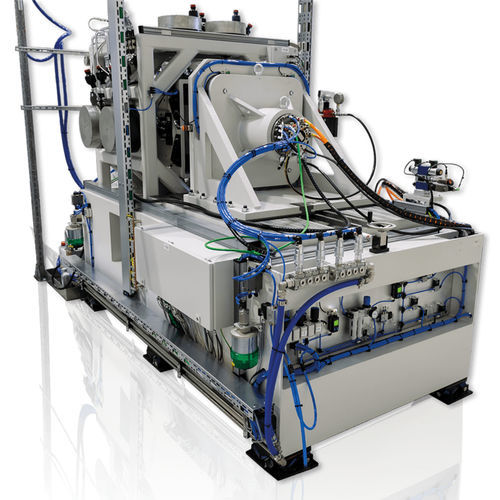

The development/laboratory test stand for motor spindles is used to test dynamic loads and perform extensive long-term testing. The testing process is controlled by means of a modular software architecture that is visualised on two monitors. Testing processes can be individually programmed and customised by the user.

Testing software and HMI

Test procedures under load with hydraulic diaphragm cylinders

Runout measurement with LC50-DIGILOG

Testing processes

•Long-term analyses

•Life-cycle test

•Load test

•Vibration test

•Torque test

•Maximum rotation speed test (under load)

•Comparison test (e.g. different lubrications)

•and much more...

Measuring sizes

•Rotation speed

•Forces (axial/radial)/bending moment

•Torque

•Temperatures (bearing, cooling water, coil)

•Displacement axial/radial

•Vibrations/oscillations

Equipment

•Sliding unit for holding specimen

•Bearing housing for load motor with hydraulically controlled positioning cylinders

•Fixed-integrated specimen

•Oil mist lubrication for specimen bearings

•Cooling water unit