Shaft measuring machine geometryshapeautomatic

Add to favorites

Compare this product

Characteristics

- Measured physical value

- geometry, shape

- Operating mode

- automatic

- Measured material

- shaft

- Other characteristics

- high-precision, high-speed

Description

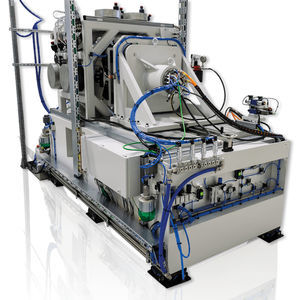

The multipoint measuring machines for rotationally symmetric workpieces offer quick acquisition of component geometry during dynamic measurement. Loading is possible manually as well as automatically. Its loading position is easy accessible from above right on top of the final measuring position.

•Quick acquisition of component geometry

•Ultra-precise measurements guaranteed by the use of high-quality individual sensors

•Fast and flexible acquisition of shaft geometry

Your benefit

•Post-process multipoint measuring system with independent PLC

•Easy integration into existing automation system

•Short, optimised feed motions

•Flexibly configurable measuring unit using measuring forks/callipers with intelligent universal •clamping system

•Manual or automated loading/unloading

•High availability due to reduced changeover time

•Additional changeover monitoring (poka-yoke principle)

•Automatic calibration device

•Also available as measuring system for external control

Variant

•Dynamic testing for geometry and form

•Static geometry testing

VIDEO

Catalogs

No catalogs are available for this product.

See all of Blum-Novotest‘s catalogsRelated Searches

- Measuring machine

- Test stand

- Automatic test stand

- Micrometer

- Optical measuring machine

- Automatic measuring machine

- Pressure test stand

- Industrial test bench

- High-precision measuring machine

- Touch probe head

- Measuring system for industrial applications

- Parts measuring machine

- Hydraulic test stand

- Manual test stand

- Control measuring machine

- Measurement touch probe head

- Non-contact measuring machine

- Laser measurement system

- Test stand for the automotive industry

- Material test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.