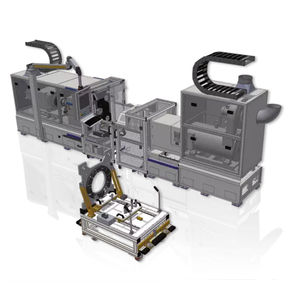

Clutch test stand pressure leakautomaticfor assembly lines

Add to favorites

Compare this product

Characteristics

- Test type

- pressure leak

- Operating mode

- automatic

- Test material

- clutch, for assembly lines

- Technology

- oil-filled

Description

The test stand is designed to allow fully automated leak testing, oil filling and function tests for clutches in rear-axle drives. As an “end-of-line” test stand, it is integrated into an assembly line. Specimens are rear-axle drives with an integrated differential, which are equipped with a hydraulically operated multi-plate clutch.

•Oil filling at an inclined position

•Function test

•Drive unit with torque measurement flange

Functional test/EOL test

•Software version check: Comparison of the software version in the control units with the current stored and released version number.

•Venting hydraulic system: Trigger a venting routine in the control unit using a diagnostics job and remove the remaining air.

•Measurement of adjustment accuracy: Record and evaluate the clutch curve using a pre-defined speed-torque profile.

Oil filling

Filling the rear axle differential with the operating medium in the optimal filling position. For dosage the correct volume of oil, a batcher with the ASR 20 control system is used

Leak test

Evaluation of leakage rate by means of leak test computer (1000 mbar)

Catalogs

No catalogs are available for this product.

See all of Blum-Novotest‘s catalogsOther Blum-Novotest products

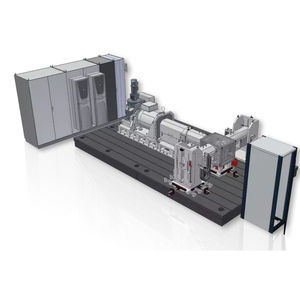

Test Engineering - transmission test stands

Related Searches

- Measuring machine

- Test stand

- Automatic test stand

- Micrometer

- Optical measuring machine

- Automatic measuring machine

- Pressure test stand

- High-precision measuring machine

- Industrial test bench

- Touch probe head

- Measuring system for industrial applications

- Parts measuring machine

- Hydraulic test stand

- Manual test stand

- Control measuring machine

- Measurement touch probe head

- Non-contact measuring machine

- Laser measurement system

- Test stand for the automotive industry

- Material test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.