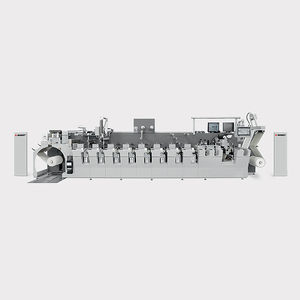

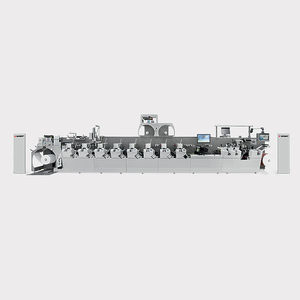

In-line flexographic press M6for paperfor plastic filmcarton

Add to favorites

Compare this product

Characteristics

- Type

- in-line

- Application

- for paper, for plastic film, carton

- Other characteristics

- for packaging

Description

The UV Digital Flexo press for food packaging

M6 line, the press which changes the future of Flexible Packaging. A combination of in-line UV Flexo, REVO Digital Flexo and the new revolutionary V-Flower print unit allow for job change overs literally in 1 minute, "on-the-fly" without stopping the press, with up to 95% press up-time. The most productive press to economically produce ultra short up to mid runs. A new Flexible Packaging job can literally start production in 1 minute, with the highest print quality ever. And the highest health safety for the final consumer, also for food packaging.

Short web path on over-dimensioned chilled drums for “positive” web transportation and accurate temperature control on most “delicate” substrates. Also LLDPE can be printed, as well as 15 microns BOPP, alufoil and cartons, on the same press, with excellent register stability

No VOCs, totally inexistent risk of fire, explosions on press or in the company due to ink solvents etc.

No solvent recovery etc. Very limited safety constraints. Ink can be stored in non-explosion proof rooms

Easy and fast press installation or move anywhere in the production site - easy press relocation

Clean working environment, without solvents in the air - no odours

No need to wash the print units during shift changes, the ink stays in the tray without evaporating, for days

Exceptional print quality, up to 80 lines per cm/200 lines per inch, and more

No need of highly skilled operators due to the simplicity of the UV Flexo process

VIDEO

Catalogs

No catalogs are available for this product.

See all of BOBST‘s catalogsRelated Searches

- Printing machine

- Color label printer-applicator

- Paper label printer-applicator

- Flexographic press

- Automatic label printer-applicator

- Hot foil stamping machine

- Offset printing machine

- Rotogravure printing machine

- High-speed label printer-applicator

- Label label printer-applicator

- In-line flexographic press

- Packaging printing machine

- Paper flexographic press

- Sheet fed offset printing machine

- 8-color flexographic press

- Paper hot foil stamping machine

- Plastic film flexographic press

- 6-color flexographic press

- Packaging flexographic press

- In-line label printer-applicator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.