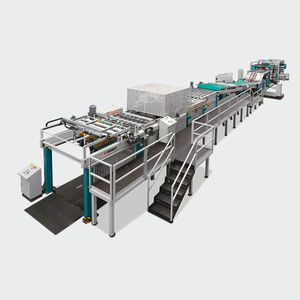

Vacuum metallizing system oneBARRIERfor paper

Add to favorites

Compare this product

Characteristics

- Type

- vacuum, for paper

Description

Overcoming the technical complexities of developing and manufacturing sustainable high barrier flexible packaging that is recycle-ready is a major challenge, even more so since the market looks for new solutions with the right barrier performances to replace the multi-material non-recyclable packaging.

With oneBARRIER, BOBST has undertaken a design and testing project that is creating industrially viable recycle-ready mono-material ultra-high and high barrier duplex and triplex substrates for packaging designers as alternatives to non-recyclable metallized polyester film. Developed with leading industry partners, the family of BOBST oneBARRIER sustainable solutions to date includes PrimeCycle, comprising EVOH and topcoat-free transparent AlOx-based or opaque AluBond-based full PE mono-substrates, and FibreCycle, a mono-material high-barrier paper-based structure coated with functional layers that can be recycled in the existing paper stream.

The BOBST & Partners oneBARRIER solutions are the outcome of joint process and equipment development and testing. The advantages for converters are manyfold:

• Integrated package solution: process-machine-output in one flow

• Knowledge of both coating and vacuum metallizing equipment technology and processes from a single supplier

• Different kinds of raw material specifications, coating, and adhesive chemicals

• Guaranteed barrier properties of the full structures (pre-coat + metallization + post coat + eventually lamination)

Catalogs

No catalogs are available for this product.

See all of BOBST‘s catalogsRelated Searches

- Production machine

- Automatic making machine

- Plaiting machine

- High-speed production machine

- Automatic folding machine

- Laminating machine

- Single making machine

- Precision plaiting machine

- Folding production line

- Paper folding machine

- Cardboard production line

- Metallizing system

- Vacuum laminating machine

- Vacuum metallizing system

- Cardboard folding machine

- Gluing production line

- In-line laminating machine

- Solvent-free laminating machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.