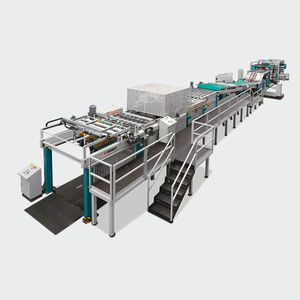

Packaging coating and laminating machine EXPERTLAM 900

Add to favorites

Compare this product

Characteristics

- Applications

- for packaging

Description

The modular and widely flexible design of the EXPERTLAM 900 is a result of the evolution of BOBST high-end laminators taking productivity to the next level. Combining BOBST extensive coating and laminating know-how in one single solution. Along with superior product quality and operator friendliness, upgradeability is also a distinctive feature of this coater-laminator that can be converted to tandem configuration any time after installation to meet the customer's changing production requirements. The EXPERTLAM 900 can be purchased as a basic laminating machine, taking the heritage of the VISION D850, or equipped with Barrier packages dedicated to the production of recyclable film and paper packaging.

Highly versatile and efficient

• Multi-trolley design for different process technologies including rotogravure, flexo coating, solvent-less, flexo printing, pressurized chamber and twin roll trolleys to cover a wide array of coating and laminating applications such as: solvent-based and water-based dry lamination, solventless lamination, in register cold seal coating on pre-printed substrates, in-register printing of one additional color and barrier coating

• Ideal for medium to large sized converters willing to diversify into coating applications such as barrier, thanks to the high configurability of the machine incorporating all the considerable advantages of BOBST Coating technology

• Hybrid dryer up to 5 sections (for a total of 12 m dryer) with dual technology nozzles obtaining maximum efficiency from the drying process

Catalogs

No catalogs are available for this product.

See all of BOBST‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.