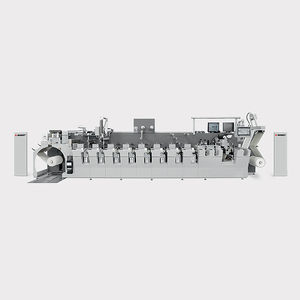

UV inkjet printing press LEMANIC® M6for paperfor packagingcolor

Add to favorites

Compare this product

Characteristics

- Printing technology

- UV inkjet

- Applications

- for paper, for packaging

- Number of colors

- color

- Other characteristics

- high-speed, automatic, in-line

Description

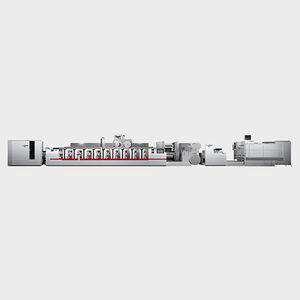

The LEMANIC® M6 produces high quality finished blanks in a single inline machine pass. This innovative machine leverages the reputed BOBST's inline flexo printing technology and the LEMANIC® converting expertise into a unique production line.

BOBST innovations in flexo technology such as smartSet or oneECG Extended Color Gamut printing deliver unprecedented workflow efficiency, color consistency and repeatability. This is complemented by the press' flexibility to use UV and water-based inks, as well as numerous inline embellishments possibilities.

The line's printing and converting assets, including multiple post-print solutions such as in-line flat-bed or rotary converting, brings high agility to meet brand owners' requirements. It also offers innovative and diversified solutions to the general folding carton market targeting short & medium production volumes.

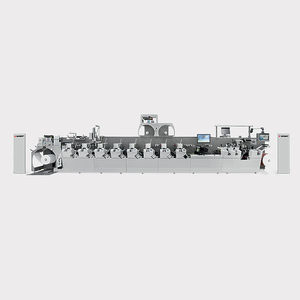

Unprecedented agility

• The LEMANIC® M6 modular and evolutive configuration flexibility allows the progressive integration of the latest processes to match the changing market trends:

• handles a wide range of substrates including paper, cartonboard, PE coated and metallized board up to 400gsm

• UV or water-based printing for food-safe packaging applications

• countless in-line process combinations for innovative and sophisticated packaging solutions, including lamination, cold-foil, back printing and gravure printing

• Complex graphics features can be processed for food and non-food packaging.

Catalogs

No catalogs are available for this product.

See all of BOBST‘s catalogsRelated Searches

- Printing machine

- Color label printer-applicator

- Paper label printer-applicator

- Automatic label printer-applicator

- Flexographic press

- Hot foil stamping machine

- Offset printing machine

- Rotogravure printing machine

- High-speed label printer-applicator

- Label label printer-applicator

- In-line flexographic press

- Packaging printing machine

- Paper flexographic press

- Sheet fed offset printing machine

- 8-color flexographic press

- Paper hot foil stamping machine

- Plastic film flexographic press

- 6-color flexographic press

- Packaging flexographic press

- In-line label printer-applicator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.