- Production Machines

- Plastics Processing

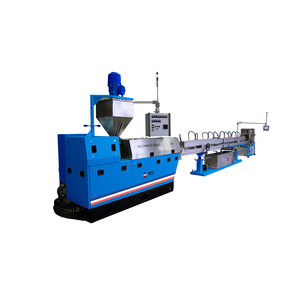

- Tube extrusion line

- BOCO PARDUBICE machines, s.r.o.

Tube extrusion line for thermoplasticsfor HDPE

Add to favorites

Compare this product

Characteristics

- Type

- tube

- Treated material

- for thermoplastics, for HDPE

Description

Extrusion lines for production of pipes and tubes

The screw of the extruder equipped with a barrier unit and mixing structure, and the barrel owns new style grooves. All of them offer good plastification and mixing effect. Special design of basket die head for HDPE (PP, ABS), large diameter pipe with a thick wall offers lower melting temperature, good mixing, lower pressure of cavity, and stable production.

Special design for sizing and cooling system by using film and water ring to cool HDPE (PP, ABS) material, which can meet the requirement of HDPE (PP, ABS). And the design can ensure the stability of diameter and roundness when producing the pipe with a thick wall. The special design of vacuum sizing tank can ensure the stability of size and roundness, speed controllers are used in the extruder, haul-off to offer stability and precision. The whole line adopts PLC control system and a large liquid crystal screen, which makes the operation very convenient.

The line can be equipped with another extruder used for extruding the mark line. Detailed Product Description1. Single screw extruder, very suitable for processing PE resin with high capacity, max capacity 1000 kg/h.

The production line adopts a reasonable design, absorbs safe producing technology, acquires CE certificate. The diameter range is 16 mm - 800 mm and it can be changed into inch standard so as to meet clients' special requirements.

Catalogs

No catalogs are available for this product.

See all of BOCO PARDUBICE machines, s.r.o.‘s catalogsOther BOCO PARDUBICE machines, s.r.o. products

EXTRUSION LINES

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Screw extruder

- Twin-screw screw extruder

- Panel extrusion line

- Pipe extrusion line

- PVC extrusion line

- Single-screw screw extruder

- Compounding screw extruder

- PP screw extruder

- HDPE extrusion line

- PE screw extruder

- ABS screw extruder

- Plastic profile extrusion line

- PVC screw extruder

- Laboratory screw extruder

- PS screw extruder

- Pelletizing screw extruder

- PC extruder

- Recycling screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.