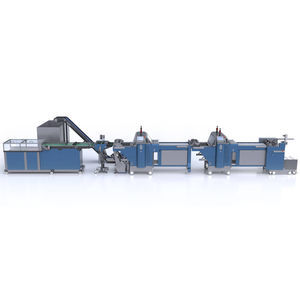

Die cutting machine BSR 550 basicsheetservo-drivenhole punch

Add to favorites

Compare this product

Characteristics

- Technology

- die

- Product handled

- sheet

- Control type

- servo-driven

- Associated function

- hole punch

- Applications

- for industrial applications

- Phase

- three-phase

- Configuration

- compact

- Other characteristics

- high-precision, rotary

- Cutting speed

110,000 mm/min

(72.178 in/s)- Weight

2,400 kg

(5,291.09 lb)

Description

The compact and attractively priced BSR 550 basic is structured as an offline solution. It is designed specifically for users who want to produce small and medium runs economically and efficiently as well as for those for which the flexible connection options and technical features of the BSR 550 Servo have no priority.

Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail.

The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping.

To exchange the flexible dies the entire breakout and deliver unit is disconnected from the die-cutting area. Thus an optimal accessibility is guaranteed.

After die-cutting the inner cuts are separated and the waste matrix is deflected.

By default, the BSR 550 basic is equipped with a unit of 5 air nozzles. Each air blast nozzle can be fitted and adjusted without tools. For deflecting the section grids and for the gripping and delivering of the products, break out elements with pulleys are used. These elements can also be fitted and adjusted without tools.

Following the die-cutting and waste stripping process each product is delivered on the stream belt (length 1 m). This stream belt is height adjustable by a motor and is provided with a delivery table. This table can be easily removed, if required.

VIDEO

Related Searches

- Cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet cutting system

- High-performance cutting system

- Three-phase cutting system

- Compact cutting system

- Rotary blade cut-off machine

- Punching center

- Paper cutting system

- Automatic punching press

- Multi-function cutting system

- Modular cutting system

- Die cutting machine

- Hole punch cutting system

- Servo-driven cutting system

- Punching machine punching machine

- Cardboard cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.