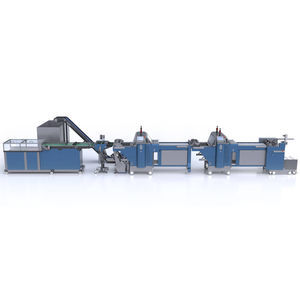

Servo-driven cutting machine BSR 550 Servodiefor cardboardfor paper

Add to favorites

Compare this product

Characteristics

- Technology

- die

- Material

- for paper, for cardboard

- Product handled

- sheet

- Control type

- servo-driven

- Applications

- for industrial applications

- Phase

- three-phase

- Configuration

- compact

- Other characteristics

- automatic, high-precision, high-performance, roller

- Cutting speed

165 m/min

- Weight

3,000 kg, 3,640 kg

(6,613.87 lb, 8,024.83 lb)

Description

Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail.

The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching punching cylinder with high precision without stopping.

Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation.

Automatic deflection of waste matrix and simultaneous separation of inner cuts increase production in addition.

The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h.

VIDEO

Related Searches

- Cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet cutting system

- High-performance cutting system

- Three-phase cutting system

- Rotary blade cut-off machine

- Compact cutting system

- Paper cutting system

- Multi-function cutting system

- Die cutting machine

- Modular cutting system

- Hole punch cutting system

- Servo-driven cutting system

- Cardboard cutting machine

- Rotary cutting system

- Packaging cutting system

- Roller cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.