- Environment - Health - Safety

- Waste Treatment

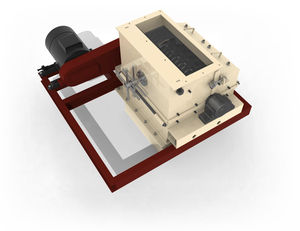

- Granulator

- BOHEMIA MACHINE

Granulator

Add to favorites

Compare this product

Description

This drum granulator is a machine designed for continuous granulation of melted glass. The drum is mounted on two pairs of driving rollers in the supporting frame of the granulator, and it is locked in longitudal direction with axial rollers.

Inner surface of the drum is equipped with a spiral which moves the melted or granulated glass. Regarding the fact that the granulated glass only rolls over the inner surface of the drum, its abrasive wear is very low, whereas both durability and reliability of the machine are high. Water level is determined with the drum design. The inlet drum side is equipped with a circular ring and the other side is tapered. The machine slopes towards the inlet or outlet side, and this effects overflow of the cooling water. The drum is driven with an electric gearbox through a chain and friction drive. The melted glass is chuted in the drum. The time of granulation in the drum can be set with the drive revolutions. The cooling water is either chuted in the drum together with the melted glass, or it is fed separately through the drum inlet or outlet. An electric switchboard with switches, circuit breakers and frequency changer of revolutions makes a part of the machine. Capacity of the granulator depends on customer’s requirements.

Catalogs

No catalogs are available for this product.

See all of BOHEMIA MACHINE‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.