Combustion furnace BM-Piafchamberprogrammable

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Heat source

- combustion

- Other characteristics

- programmable

- Maximum temperature

Min.: 0 °C

(32 °F)Max.: 1,470 °C

(2,678 °F)700 °C

(1,292 °F)

Description

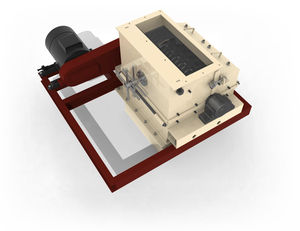

A SINGLE-POT FURNACE, produced and offered by Company Bohemia Machine s.r.o., Světlá nad Sázavou, has a unique design in order to use the input energy as much as possible.

The combustion air is preheated in a heat-radiating steel recuperator up to a temperature of 350°C, and then it is heated further in a special electrically-heated box up to 1000°C (such a temperature is mostly used for heating up pot furnaces to its operational temperature prior to lighting the burner). Under standard operational procedures, the temperature of the pre-heated air ranges from 650°C to 700°C. It means the temperature of the burner is always above the ignition temperature of natural gas.

The steel furnace structure carries a special refractory concrete skeleton, in the low section of which there is a natural gas combustion chamber; the exhaust gases stream up, flow around the pot, are discharged to the cupola booth over the pot, and enter the recuperator. The working area of the pot furnace is separated from the exhaust gases area by a refractory concrete box that opens into the furnace port. The refractory concrete skeleton can house pots up to a standard size of 60 x 60 and a volume of 85 liters, which represents approximately 240 kg of lead crystal. Both electric and gas heating is controlled and regulated with programmable automatic units.

Practical experience shows that the natural gas consumption is up to 5 Nm3/hour. An efficient consumption such as this can be achieved due to a unique system of combustion gas heating and to abundant insulation of the whole set with fibrous insulation materials. The surface temperature of the steel sheet furnace bodywork does not exceed 100°C.

Catalogs

POT FURNACE BM-PIAF

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.