- Machine-tools

- Finishing Machine

- Glass polishing machine

- BOHEMIA MACHINE

Glass polishing machine industrialsurface

Add to favorites

Compare this product

Characteristics

- Machined material

- for glass

- Domain

- industrial

- Other characteristics

- surface

Description

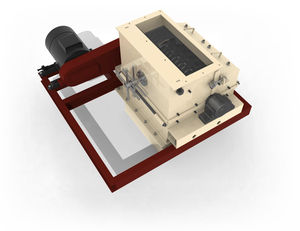

LIZA L5/2000: Flame-Polishing machine

This is a linear polishing machine in automatic glass production that is designed for slow glass surface polishing cycles. Cycle 0,25 to 2,5 pcs/min. Polishing is achieved with flame after pressing the glass article prior it is moved into an annealing oven. A control and visual systems are a part of the machine. The machines can be set in a line for polishing one side of the product, its turning, and subsequent polishing of the other side. The turning device is supplied depending on the line type.

The polishing machine consists of a chain conveyor whose links are small desks equipped with revolving plates that can move along a linear track. 5 upper positions are technological ones (1 feeding position, 3 polishing positions and 1 removing position). The desks return back below to the feeding position from the removing position. The base of the machine consists in a steel construction. The positions are moved with a servomotor and transmission. All 5 upper positions are equipped with their own servomotor driving mechanisms for turning the plates. In the feeding and removing positions the article is turned appropriately to the handling equipment. In the polishing positions the article rotates in front of the burner. When moving the positions, the driving mechanisms of the plates are disengaged as they are swung away with a pneumatic cylinder, and the revolving of plates is mechanically locked.

Catalogs

No catalogs are available for this product.

See all of BOHEMIA MACHINE‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.