- Detection - Measurement

- Flow, Pressure and Level Measurements

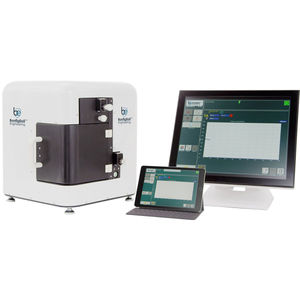

- Mechanical leak tester

- Bonfiglioli Engineering S.r.l.

- Products

- Catalogs

- News & Trends

- Exhibitions

Mechanical leak tester PK-VIS for full containersin-linehigh-speed

Add to favorites

Compare this product

Characteristics

- Type

- mechanical

- Applications

- for full containers

- Other characteristics

- automatic, in-line, high-speed

Description

-High inspection solutions flexibility

-High stability of application system and validation principles

-Hardware and Software optimization according to customer URS

-AVI no limited visual defects detection

-CFR part 11 compliance and 4.0 full integration

Technical Features

-Container Application: Ampoules, BFS, Carpoules, Vials, Bottles

-Products: Powder, Lyo, Liquid

-Container Dimensions: Diam. 14 - 54 mm

-Fill level: [1 - 100] ml

-Speed: Up to 600 Cpm

-Technology: AVI (Automatic Visual Inspection)

-Inspection Features: Non-Invasive, Non-Destructive

-Inspection Capabilities: Visual inspection: - Presence of Foreign Particulate Matters, - Cosmetic Defects,- False Fill Level and Product Color.

Additional Benefits

-Computer-based automated measurement system: image acquisition, processing, and decision making.

-High resolution cameras coupled with illuminators automatically positioned so to magnify regions of interest and designed according to defect type.

-Maximum accessibility of electrical and mechanical component for easy maintenance.

-Connections to Active Directory and VPN router for machine remote access.

-Validation package guarantees complete and efficient regulatory compliance.

-Full batch control testing: fast, reliable and repeatable.

-Testing of all nominal production line speed.

-MES (Manufacturing Execution System connection) allows remote machine data exchange & download

-Real time display of statistical raw data

-Easy, quick and safe remote access

-Easy cleaning

Technology

It is an automated camera based measurement technology detecting visual defects,

VIDEO

Other Bonfiglioli Engineering S.r.l. products

Pharmaceutical

Related Searches

- Leak testing device

- Pressure leak testing device

- Automatic leak testing machine

- Packaging leak testing device

- Vacuum leak testing machine

- Bottle leak testing machine

- Vessel leak testing device

- Compact leak tester

- Pneumatic leak test bench

- In-line leak tester

- Empty container leak tester

- Flow leak testing device

- High-speed leak tester

- Tabletop leak tester

- Multi-head leak tester

- Aerosol can leak tester

- Container leak tester

- Full container leak tester

- Mechanical leak test bench

- Rotary leak tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.