- Detection - Measurement

- Flow, Pressure and Level Measurements

- Vacuum leak tester

- Bonfiglioli Engineering S.r.l.

- Products

- Catalogs

- News & Trends

- Exhibitions

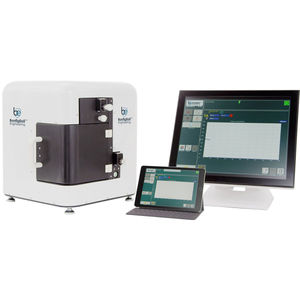

Vacuum leak tester LF-SMHpressurevacuum decayfor packaging

Add to favorites

Compare this product

Characteristics

- Type

- vacuum, vacuum decay, pressure

- Applications

- for packaging

- Other characteristics

- compact

Description

Non-Invasive, Non-destructive Integrity Inspection System for finished and filled containers for in process and off-line control applications.

Highlights

Quick and sensitive test

Zero alteration of container features

Vacuum and positive pressure testing

Fast, reliable and repeatable results

Highly functional, intuitive HMI

Cost-effective solution

System autodiagnostics available

Technical Features

Container application: Ampoules, Vials, Pouches, MDPI, MDI, IV Bags, Flowrapped Device, Flowpacks PFS, Carpoule, Bottles.

Products: Filled, Empty, Closed

Container dimensions: From 5 x 30 x 5 mm (min) to 86 x 86 x 250 mm (max)

Speed: Up to 20 cpm

Technology: CCIT

Inspection features: Non-Invasive, Non-Destructive CCIT based on Vacuum Decay Method

Inspection Capabilities: Microleaks detection

Additional Benefits

Compact and robust design

Maintenance-free

Quick change over

Low power consumption

Storage, maintenance, and download of historical data (production, raw data, events, alarms)

HMI Real Time display of Testing Cycle diagram

Computerised system is designed to comply with FDA 21 CFR Part 11 and EU Annex 11

Validation Package guarantees complete and efficient regulatory compliance

Technology

Container Closure Integrity Testing is a non-destructive measurement technology based on Vacuum Decay Method.

Measurement system comprises applying a pressure differential into an airtight testing group enclosing the container.

The test objective is to detect container leakages by measuring the reached pressure level as well as the pressure change over test time.

VIDEO

Other Bonfiglioli Engineering S.r.l. products

Pharmaceutical

Related Searches

- Leak testing device

- Pressure leak testing device

- Automatic leak testing machine

- Packaging leak testing device

- Vacuum leak testing machine

- Bottle leak testing machine

- Vessel leak testing device

- Compact leak tester

- Pneumatic leak test bench

- In-line leak tester

- Empty container leak tester

- Flow leak testing device

- High-speed leak tester

- Tabletop leak tester

- Multi-head leak tester

- Aerosol can leak tester

- Container leak tester

- Full container leak tester

- Mechanical leak test bench

- Rotary leak tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.