- Detection - Measurement

- Flow, Pressure and Level Measurements

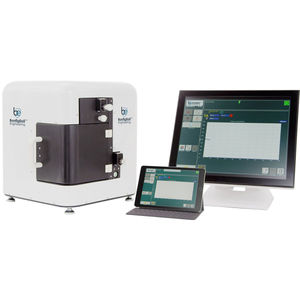

- Vacuum leak tester

- Bonfiglioli Engineering S.r.l.

- Products

- Catalogs

- News & Trends

- Exhibitions

Vacuum leak tester PK-Vpressurefor full containersfor bottles

Add to favorites

Compare this product

Characteristics

- Type

- vacuum, pressure

- Applications

- for bottles, for full containers, for vials

- Other characteristics

- automatic, in-line, high-speed

Description

-Autotest in real time

-Easy to validate

-CFR 21 part 11 compliance and 4.0 full integration

-Quick format changeover

-High installation flexibility

-Automatic Drying System, no testing chamber contamination

Technical Features

-Container Application: Vial and Bottles (Glass + Plastic)

-Products: Semi-solid, Powder, Lyo, Liquid

-Container Dimensions: Standard Vials and Bottles from 2 to 250 ml

-Speed: Up to 600 Cpm

-Technology: CCIT

-Inspection features: Non-Invasive, Non-Destructive CCIT based on Vacuum & Pressure Decay Method

-Inspection Capabilities: Microleaks detection

Additional Benefits

-Full batch control testing: fast, reliable and repeatable

-Testing of all nominal production line speed

-MES (Manufacturing Execution System connection) allows remote machine data exchange & download

-Statistical Process Control reduces deviations for a better yield control

-Real time display of testing cycle diagrams, statistical raw data

-Easy, quick and safe remote access

-AHE (Automatic Head Exclusion)

-Easy cleaning

Technology

-Container Closure Integrity Testing is a non-destructive measurement technology based on the following testing methods:

-Vacuum Decay Method

-Pressure Decay Method

-Measurement system comprises applying a pressure differential into an airtight testing group enclosing the container.

-The test objective is to detect container leakages by measuring the reached pressure level as well as the pressure change over test time.

VIDEO

Other Bonfiglioli Engineering S.r.l. products

Pharmaceutical

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.