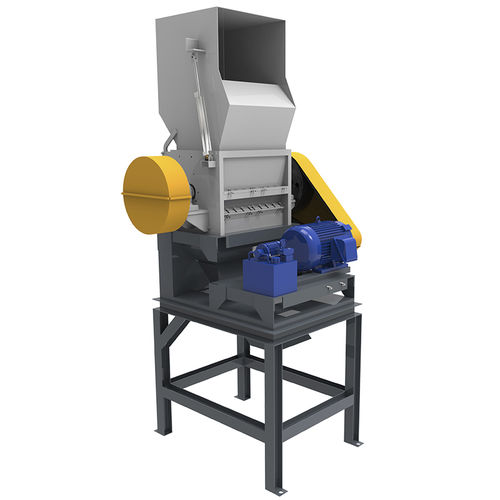

Description

BoReTech crusher is capable of wet crushing which causes friction washing to PET flakes. Meanwhile, water flushing cools down crusher blades and reduce crusher chamber temperature and blade abrasion, it reduces PET powder and loss of PET flakes, this process creates a better condition for PET flakes hot washing.

Feature

1.Crusher adopts the latest V-shaped cutting technology, shaft rotation transports PET bottles to the center of the crusher chamber,

avoids these input bottles sticking to the chamber sidewall and increases the crusher chamber's service life by reducing abrasion.

2.The Crusher blade is made of imported alloy Steel, which is wear-resistant, high hardness, and longer service life. They are

available to be sharpened and reused.

3.The crusher chamber is made of high-hardness Steel. It is processed by CNC lathe which has the advantage of great thickness,

high strength, strong wear résistance, no pollution, and long service life. What's more, it is convenient for daily maintenance.

4.A safety curtain is equipped on the inlet hopper of the crusher, it prevents PET flakes from splashing out when the crusher is under

opération.

5.The crusher pulley is connected to the drive shaft through a V-shaped belt, it is provided with the balanced opération, précisé

coordination. Besides, it's easy to repair work and maintenance.

6.The feeding hopper and screen frame are operated by a hydraulic device.

7.Rotary blades can be completed calibration in advance by tools outside the chamber, it's more convenient and safer.