- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

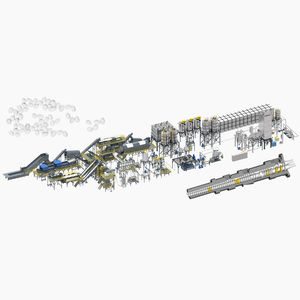

PET recycling unit TL3000-02for PVCfor PEfor HDPE

Add to favorites

Compare this product

Characteristics

- Applications

- PET, for PE, for HDPE, for EPS, for LDPE, for PVC

- Recycled product

- motor oil container, for bottles

- Functions

- crushing, washing

- Productivity

Max.: 3,000 kg/h

(6,614 lb/h)Min.: 500 kg/h

(1,102 lb/h)

Description

Waste PET bottles are the most difficult recycling material due to impurities diversity among in PET bottle bales. BoReTech has a total solution for PET bottle recycling, devoting ourselves to the PET bottle recycling industry for two decades. We provide recycling solutions for HDPE and LDPE thanks to familiarity with plastics characteristics.

Most HDPE bottles from the market are applied to fill milk, shampoo, and bath gel. HDPE bottle bales have fewer impurities, and most labels are the PP sticky label, they are easy to be separated by washing. The ink printed on HDPE bottles can be removed by the chemical and washing process. Due to the density of HDPE, it's easy to be separated from other impurities by gravity difference completely. After hot washing, friction washing, rinsing, and dust removal, HDPE flakes will be clean.

The simplified PET bottle recycling process can be applied to HDPE washing. According to customer demand, BoReTech can supply the solution which can wash HDPE and PET are combined. Customers can use this recycled HDPE flakes for granulation, or even realize the HDPE-to-HDPE circulation.

Most LDPE is an agricultural film, land film, industrial film, and urban waste film. BoReTech also provides corresponding recycling solutions according to the different waste film.

Input Capacity:500-3000 kg/h

Catalogs

Related Searches

- Crushing plant

- Screening unit

- Centrifugal classifier

- Bulk material screening unit

- Stationary crushing and screening plant

- Liquids separator

- Baling press

- Pelletizer

- BoReTech recycling unit

- Classifier for the recycling industry

- Vertical chamber baling press

- Horizontal baling press

- Plastic pelletizer

- Automatic separator

- Compact crushing and screening plant

- Recycling screening unit

- Waste granulator

- BoReTech plastic recycling unit

- Compact screening machine

- High-efficiency classifier

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.