- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

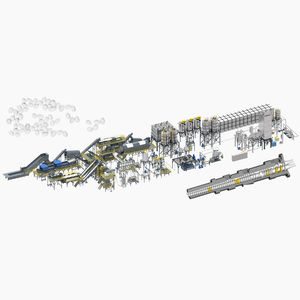

PET recycling unit TL3000-03metal separationfor process lines

Add to favorites

Compare this product

Characteristics

- Applications

- PET

- Functions

- metal separation

- Other characteristic

- for process lines

Description

The PET bottle recycling industry is gradually moving towards standardization and maturity. Reasonable washing process and configuration can realize the automation and intelligence of the recycling system. The following auxiliary systems of the washing line can improve the quality of the final product, reduce labor input, and obtain the greatest added value. It can be selected according to different demands and applications.

Automatic Detergent Dosing System

The automatic detergent dosing System is applied to the bottle pre-washing and hot washing section. Through the metering pump, safety valve, and other devices, the preset program can préparé washing Chemicals under the formulary ratio and dose it to needful machines automatically. By in-line real-time monitoring of Chemical concentrations, the System automatically doses prepared washing Chemicals according to rPET flakes quality requirement and/or cleanness of raw material and saves manpower.

Online Water Saving System

There are lots of wastewater that will be produced in the bottle pre-washing, hot washing, and rinsing of PET bottle recycling. The online water-saving System collects, treats, and filters wastewater to achieve online water reuse. It greatly reduces water consumption. Over 50% of rinsing water can be processed to reach the quality requirement of industrial water for reusing it in the rinsing process, which saves water consumption. Chemical A Chemical B Used Rinsing Water Water Tank Treated Water for Reuse Sludge Tank Access to Waste Water Pit

Catalogs

Related Searches

- Crushing plant

- Screening unit

- Centrifugal classifier

- Bulk material screening unit

- Stationary crushing and screening plant

- Liquids separator

- Baling press

- Pelletizer

- BoReTech recycling unit

- Classifier for the recycling industry

- Vertical chamber baling press

- Horizontal baling press

- Plastic pelletizer

- Automatic separator

- Compact crushing and screening plant

- Recycling screening unit

- Waste granulator

- BoReTech plastic recycling unit

- Compact screening machine

- High-efficiency classifier

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.