- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

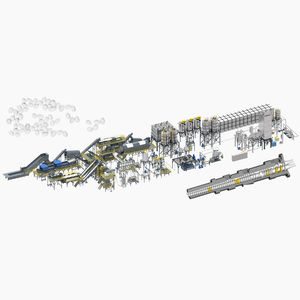

PET recycling plant TL1500-05for bottlesfor the food industrycrushing

Add to favorites

Compare this product

Characteristics

- Applications

- PET

- Recycled product

- for bottles, for the food industry

- Functions

- crushing, with pelletizing

- Other characteristic

- for process lines, for the food industry

Description

The food-grade PET bottle recycling line is mainly used for PET bottle-to-bottle project (FDA Approval), which recycles post-consumer PET bottles into rPET flakes. The regenerative PET flakes conform to the quality index requirements of downstream food packaging and are used for bottle blowing and packaging which can directly contact food after pelletizing and SSP processes in the late stage.

PET bottle bales are sorted, crushed, and washed by the food-grade PET bottle washing line, and finally generated high-quality rPET flakes. A number of well-known customers of BoReTech have obtained FDA approval of rPET flakes and supply these PET flakes to downstream brand beverage manufacturers.

Highlights

1. Solutions for diversification of PET bottle bales;

2. Automatic de-baling technology, reduces labor, a strong bale breaking ability for high-density PET bottle bales;

3. Patent technology for PVC label removal;

4. Patented Pre-washing and hot washing process to ensure the cleanliness of rPET flakes;

5. Integrated technology and capability for automatic sorting machine and PET bottle recycling line;

6. The hot washing process reduces impurities content to achieve food-grade index;

7. Stable and reliable quality of rPET flakes, online inspection to ensure the stability of rPET flakes;

8. Completed online water recycling treatment system for pre-washing, hot-washing and rinsing.

9. Low operation breakdown, production management guidance service for the customer;

Input Capacity:1500-9000 kg/h

Catalogs

Related Searches

- Crushing plant

- Screening unit

- Centrifugal classifier

- Bulk material screening unit

- Stationary crushing and screening plant

- Liquids separator

- Baling press

- Pelletizer

- BoReTech recycling unit

- Classifier for the recycling industry

- Vertical chamber baling press

- Horizontal baling press

- Automatic separator

- Plastic pelletizer

- Compact crushing and screening plant

- Recycling screening unit

- Waste granulator

- BoReTech plastic recycling unit

- Compact screening machine

- High-efficiency classifier

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.