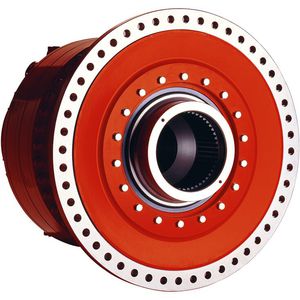

Radial piston hydraulic motor Hägglunds VIindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- radial piston

- Other characteristics

- industrial

- Pressure

Min.: 0 bar

(0 psi)Max.: 320 bar

(4,641 psi)- Rotational speed

Min.: 25 rpm

(157.08 rad.min-1)Max.: 200 rpm

(1,256.64 rad.min-1)- Torque

Min.: 53 Nm

(39.09 ft.lb)Max.: 605 Nm

(446.23 ft.lb)- Displacement

Min.: 3,325 cm³

(112.43 US fl oz)Max.: 38,000 cm³

(1,284.93 US fl oz)

Description

The Hägglunds VI motors are of radial piston type with rotating case. The case is supported on the stationary cylinder block (5) by two main bearings. An even number of radially positioned pistons (3) work in cylinder bores in the cylinder block, which also houses the inlet and out let ports (A and C). Each piston is coupled by a piston rod (2) to a cross head pin (6) upon which four cam rollers (7) are

mounted. The two inner cam rollers press against the cam ring (8) while the two outer rollers work within their respective guide plates (1). The cam ring is anchored to the rotating case. The distributor (4) directs the input oil to the pistons during their work strokes and returns the exhausted oil back to the tank. The distributor is coupled to the rotating case via a safety coupling (9).

The motor can be connected to a driven machine via two mounting surfaces on the rear end of the motor.

The symmetrical design of the motor has made it possible to construct it as a 2-speed motor. This means that two different speeds are obtained for a given flow.

The simplest way of performing displacement change over is by connecting a special valve, known as a 2-speed valve, direct to the connecting flange on the cylinder block.

The motor is designed so that pressure pulsations in the motor case are avoided.

This has the advantage that impurities are not sucked into the case

Catalogs

No catalogs are available for this product.

See all of Bosch Rexroth Hägglunds‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.