Blade cutting system 520 LAMefor glasssheetfor industrial applications

Add to favorites

Compare this product

Characteristics

- Technology

- blade

- Material

- for glass

- Product handled

- sheet

- Applications

- for industrial applications

- Configuration

- bridge

- Other characteristics

- automatic

- Cutting speed

100,000 mm/min

(65.617 in/s)

Description

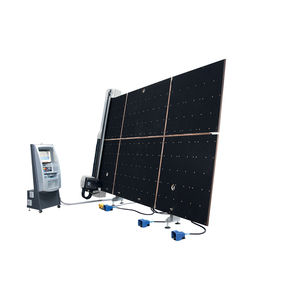

520 LAMe is out best-seller meeting any customer’s need for the production of laminated glass. The automatic control of all parameters concerning the glass cut and positioning, and the possibility of removing a glass piece of 20 mm only, together with the removal of the low-e are the top class features of this machine.

Bottero’s portfolio of laminated glass cutting products meets any possible production needs in terms of formats and thickness, and ensures excellent cutting results even in case of 12+12 mm sheets.

The positioning bridge, manual for 511LAM-S and automatic for 515LAMe and 520LAMe, helps the glass handling operations. The high density felt guarantees the best air floatation and avoids that glass chips get stuck inside with consequent potential scratching on the lower surface of glass sheets

The pneumatically operated arms on the working table allow smooth tilt of the glass sheet. Engineered to handle considerable weights and dimensions, these arms are the ideal instrument to efficiently load and unload large sheets.

The air cushion fan is directly fitted on the machine frame in order to obtain the max efficiency on the air cushion system. The shut-off system installed on the fan inlet allows the immediate interruption of the air cushion and, consequently, the risk of glass shifting

Catalogs

Laminated Cut

23 Pages

Flat Glass General Catalogue

49 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.